60

Fan speed control

For correct operation of the unit with different outside temperatures, the microprocessor controls the fan speed

based on the pressure reading from the pressure probe, thus enabling heat exchange to be increased and/or

decreased, maintaining the condensing or evaporation temperature practically constant.

The fan functions independently of the compressor.

Frost prevention alarm

To prevent the water freezing and damaging the heat exchanger, the microprocessor shuts down the compressor if

the temperature measured by the heat exchanger outlet temperature sensor is less than 3°C. The frost prevention

temperature set point can be modified by an authorized service center only and only after verifying that the water

circuit contains antifreeze. Tripping of this alarm shuts down the compressor but not the pump, which remains

active. To reset normal functions, the outlet water temperature must rise to more than +8°C. Reset is manual.

Water flow alarm

The microprocessor provides for management of a water flow alarm controlled by a pressure diference switch fitted

as standard on the appliance to be installed on the water delivery piping.

This safety device may trip after the first 60 seconds of pump operation when the water flow is up to speed. Tripping

of this alarm shuts down the compressor but not the pump, which remains active. To reset normal

functions, the alarm contact must be deactivated for at least 15 seconds.

When electrical current exceeds to setting value and condenser temperature over than 62°C, system will shut

down, but not returns to normal operation until the condenser temperature decreased less than 52°C.

c)Routine maintenance

Never perform any cleaning operations before having disconnected the unit from the mains power supply. If the

supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly

qualified manufacturer or its service agent or a similarly qualified.

Regular maintenance is fundamental to maintain the efficiency of the unit both in terms of operation and energy

consumption. The Technical Assistance Service maintenance plan must be observed, with an annual service which

includes the following operations and checks:

-Filling of the water circuit.

-Presence of air bubbles in the water circuit.

-Efficiency of safety devices.

-Power supply voltage.

-Power input.

-Tightness of electrical and hydraulic connections.

-Condition of the compressor contactor.

-Efficiency of the plate heat exchanger heater.

-Checking of operating pressure, superheating and sub cooling.

-Efficiency of compressor heater.

-Cleaning of finned coil (*).

-Cleaning of fan grills.

-Cleaning of condensate drain pan (if installed).

(*) For “Heat pump” appliances, the checks are to be performed quarterly.

For units installed near the sea, the intervals between maintenance should be halved.

d)Extraordinary maintenance

Never perform any cleaning operations before having disconnected the unit from the mains power supply.

Summary of Contents for AU082FYCRA(HW)

Page 1: ...ATW Service Manual SYJS 03 2019REV A Edition 2019 03 ...

Page 11: ...9 405 410 600 174 174 450 950 965 395 6 Dimensions AU082FYCRA HW Unit mm ...

Page 12: ...10 AU112 162FYCRA HW Unit mm 1490 950 380 187 405 410 600 174 174 450 170 ...

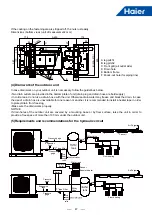

Page 13: ...11 AU082FYCRA HW 7 Piping Diagram ...

Page 14: ...12 AU112 162FYCRA HW ...

Page 27: ...25 12 Water Pressure Drop ...

Page 28: ...26 ...