17

ROSSI

GEARMOTORS

UT.D 045 rev. 5

running. For the next filling use a 60

m oil filter.

Replace the seal rings in case of dismounting or of periodical check

of gear reducer; in this case, the new ring must be positioned so that

the new ring does not work on the same sliding race of previous

ring.

When dismounting the cap (whenever gear reducers are provided

with), reset the sealing with adhesive on cleaned and degreased

mating surfaces.

9.2 - Coil

In case of long non-running periods at ambient temperatures lower

than 0 °C, the coil should be emptied out using compressed air to

blast out all the coolant, so as to avoid freezing-up which would

cause the coil to break.

9.3 - Seal rings

It is always recommended that the seal rings are replaced with new

ones when they are removed or during periodic checks of gear redu-

cer; in this case, the new ring should be generously greased and

positioned so that the seal line does not work on the same point of

sliding contact as the previous ring.

Oil seals must be protected against heat radiation, also during the

shrink fitting of parts, if applicable.

9.4 - Motor replacement

Since gearmotors are realised with

standardised

motor, motor

re placement – in case of failure – is extremely easy. Simply observe

the following instructions:

– be sure that the mating surfaces are machined under accuracy

rating (UNEL 13501-69; DIN 42955);

– clean surfaces to be fitted thoroughly;

– check and, if necessary, lower the parallel key so as to leave a

clearance of 0,1

0,2 mm between its top and the bottom of the

keyway of the hole. If shaft keyway is without shoulder, lock the

key with a pin.

For worm gearmotors MR V, parallel shaft gearmotrs MR 2I and

MR 3I 140 ... 360, right angle shaft gearmotors MR CI, C2I

(motor

shaft end keyed directly into the worm, the cylindrical or bevel pnion

shaft, respectively);

– check that the fit-tolerance (push-fit) between hole and shaft end

is G7/j6 for D

28 mm, F7/k6 for D

38 mm;

– lubricate surfaces to be fitted against fretting corrosion.

For parallel shaft gearmotors

(2I, 3I)

with motor size 200 ... 315

and gearmotors MR V, MR 2I and MR CI with non-standard

design «Square flange for servomotors», proceed as follows for

disassembling:

– align the key through hole with the tightening screw of the hub clamp;

– loosen the tightening screw and consequently the hub clamp;

– disassemble the motor.

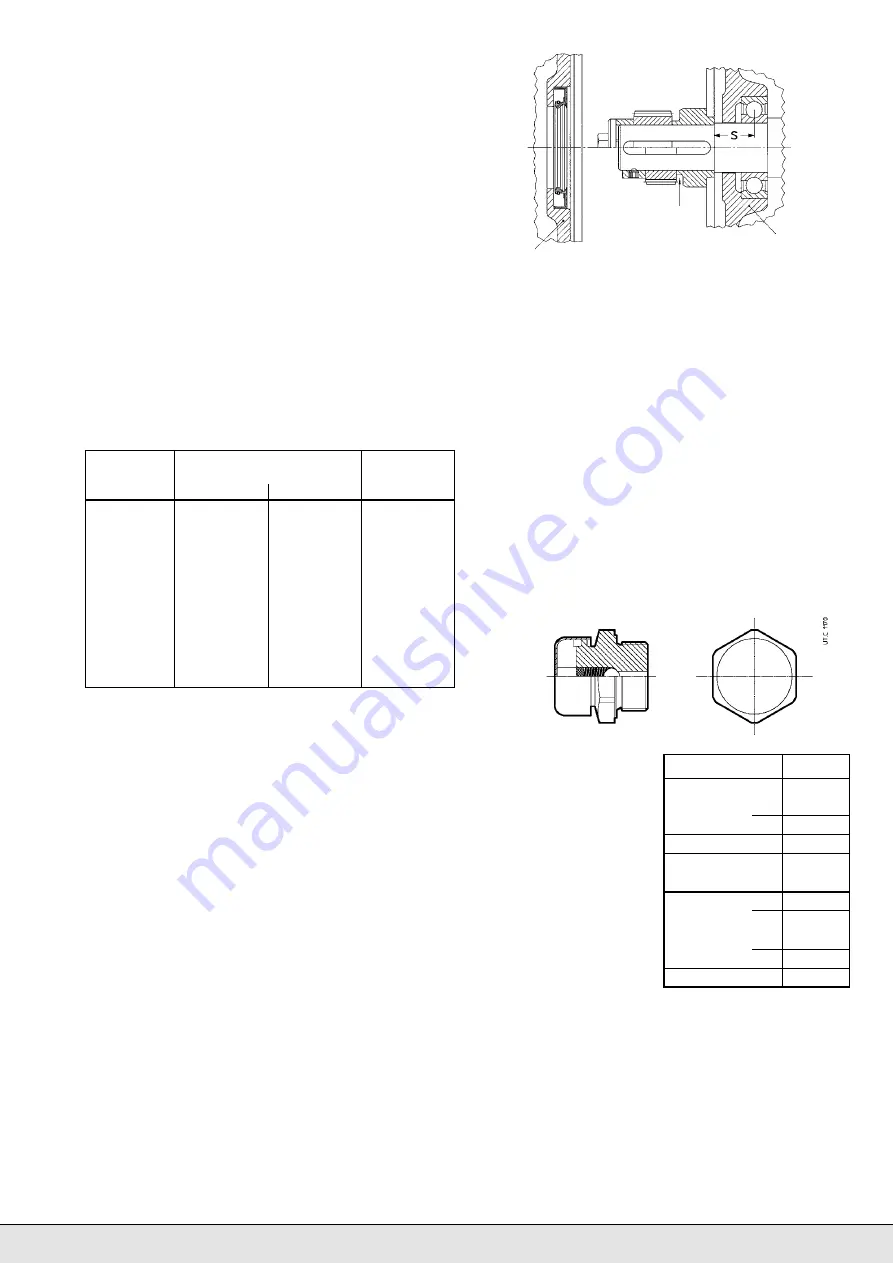

For worm gearmotors MR IV, parallel shaft gearmotors MR 3I

40 ... 125 and MR 4I, right angle shafts gearmotors MR ICI and

MR C3I, coaxial gearmotors

(cylindrical pinion keyed on to the

motor shaft end);

– check that the fit-tolerance (standard locking) between hole and

shaft end is K6/j6 for D

28 mm, and J6/k6 for D

38 mm; key

length should be at least 0,9 pinion width;

– make sure that the motors have bearing location and overhang

(distance S) as shown in the table;

– locate the spacer (with adhesive, check that between keyway

and motor shaft shoulder there is a grounded cylindrical part of at

least 1,5 mm) and pinion on the motor (pinion pre-heated to +80

+100 °C) locking the entire assembly by means of a bolt to the

butt-end or hub clamp;

– grease the pinion teeth, the sealing ring rotary seating and the ring

itself, and assemble carefully.

10 - Sound levels

Most of the ROSSI MOTORI-

DUTTORI product range is cha-

racterised

by

sound pressure

levels

L

¯

pA

(mean value of mea-

surement, assuming nominal

load and input speed

n

1

=

1 400 min

-1

, at 1 m from exter-

nal profile of gear reducer stan-

ding in free field on a reflecting

surface, according to draft pro-

posal ISO/CD 8579)

lower or

equal to 85 dB(A).

The table indicates the pro ducts

which

can exceed

a.m. thre-

shold. For further information

about sound levels of every sin-

gle

product

see

ROSSI

MO TORIDUTTORI

technical

catalogues.

Motor

Min dynamic load capacity

Max dimension

size

daN

‘S’ mm

Front

Rear

63

450

335

16

71

630

475

18

80

900

670

20

90

1 320

1 000

22,5

100

2 000

1 500

25

112

2 500

1 900

28

132

3 550

2 650

33,5

160

4 750

3 350

37,5

180

6 300

4 500

40

200

8 000

5 600

45

225

10 000

7 100

47,5

250

12 500

9 000

53

280

16 000

11 200

56

Machine/Train of gears

i

N

Size

Parallel shaft

R I

3,15

160

4

200

R 2I

all

320

R 3I

all

400

R 4I

160

500

200

630

Right angle shaft R CI

all

320

R C2I

63

400

71

500

R C3I

all

630

Right angle shaft R C

1

250

gear reducer

motor

groove for pulling

pinion

U

T.C

725

9.5 - Bearings

Since there are many different types of bearings in a gear reducer

(roller, tapered roller, straight roller, etc.) and each bearing works with

different loads and speeds depending on the input speed, the nature

of the load of the driven machine, the transmission ratio, etc., and

with different lubricants (oil bath, oil splash, grease, oil circulation,

etc.), it is not possible to define any periodical maintenance and

replacement of bearings in advance.

If a precautionally maintenance is required,

undertake periodical

checks to verify noise level and vibration with the help of appro-

piate diagniostic equipment and instruments

. If the measured

values worsen even slightly it is necessary to stop gear reducer or

gear motor and after having inspected inside the unit replace the

bearings which are subject to breakdown.

9.6 - Metal filler plug with filter and valve

When the gear reducer or gearmotor (size

100) is equipped with

metal filler plug with filter and valve (see fig. here following), in order

to clean it, it is necessary to unscrew it from the gear reducer (pre-

venting any debris or other foreign items from entering the reducer,

disassemble the cover, wash it with solvent, dry with compressed

air and reassemble it). This operation is to be made according to

environment conditions.