16

ROSSI

GEARMOTORS

UT.D 045 rev. 5

6 - Lubrication

6.1 - General

Depending on type and size, gear reducers and gearmotors may be

grease-lubricated and supplied FILLED WITH GREASE, or (synthetic

or mineral) oil-lubricated and supplied FlLLED WlTH OlL or WlTHOUT

OIL depending on type and size (see ch. 6.2). When supplying

WITHOUT OIL, the filling up to specified level (normally stated by

means of transparent level plug) is Buyer’s responsibility.

Every gear reducer has a

lubrication plate.

Concerning lubricant type and quantity, gear reducer type, how sup-

plied, plugs, filling instructions, oil-change interval, etc. see lubrica-

tion table (6.2).

Be sure that for gear reducers and gearmotors size

100, the filler

plug is provided with a valve (symbol

); otherwise, replace it

with the one normally supplied with.

When gear reducer or gearmotor is provi-

ded with a

spilway plug

(red colour) fill

after unscrewing a.m. plug in order to

check the obtained level by oil outlet.

When gear reducer or gearmotor is provi-

ded with a

level plug with rod

, fill with oil

up to specified level on rod.

When gear reducer or gearmotor is supplied with a level plug (size

100), the necessary lubricant quantity is that which

reaches a.m.

Ievel in center line of plug (gear reducer at rest)

and not the

approximate quantity given on the catalogue.

Usually bearings are automatically and continuously lubricated

(bathed, splashed, through pipes or by a pump) utilising the main

gear reducer lubricant. The same applies for backstop devices, when

fitted to gear reducers.

In certain gear reducers in vertical mounting positions V1, V3, V5 and

V6, and right-angle shaft gear reducers in horizontal positions B3, B6

and B51 (though not gearmotors in this case, for which the above

indications hold good) upper bearings are independently lubricated

with a special grease «for life», assuming pollution-free surroun-

dings. The same applies for motor bearings (except some cases in

which relubrication device is adopted) and backstop devices when

fitted to motors.

Always be sure that the gear reducer is located as per the mounting

position ordered, which appears on the name plate. When no indica-

tion is given, the gear reducer may be used in horizontal mounting

position B3 or B5 (B3, B8, worm gear reducers size

64), or vertical

position V1 (in the case of right angle shaft gear reducers in the

design incorporating flange FO1...).

Combined gear reducer units.

Lubrication remains independent,

thus data relative to each single gear reducer hold good.

6.3 - Extruder support lubrication (parallel

and

right angle

shaft)

The lubrication

of

extruder support

is

separate

from the gear redu-

cer, except:

– for designs HA ... HC;

– in presence of the independent cooling unit, if applied to lubricate

both the gear reducer and the support.

The

separate lubrication

of extruder support sensibly improves the

reliability and real life of the axial bearing; the separation between

gear reducer and support is granted by a seal ring.

With separate lubrication, for the extruder support, use polyalphao-

lephines based synthetic oil (MOBIL SHC XMP 680, CASTROL Tribol

1510/680) with

ISO 680 cSt

viscosity grade.

With

common

lubrication

(designs HA ... HC in presence of inde-

pendent cooling unit, if applied to lubricate both the gear reducer

and the support), lubricant ISO viscosity grade must be according to

the instructions given in ch. 6.2 «lubrication table» and oil must be

polyalphaolephine based synthetic type.

For the filling up of oil of extruder support, see the table below.

For the lubrication of gear reducer refer to ch. 6.2, lubrication table.

7 - Cooling system

7.1 - Cooling by fan

If there is fan on the gear reducer verify

that there is sufficient space allowing for

adequate circulation of cooling air also

after fitting coupling protection. If a cou-

pling protection is fitted (drilled case or

wire netting), smooth, the coupling hub, if

necessary.

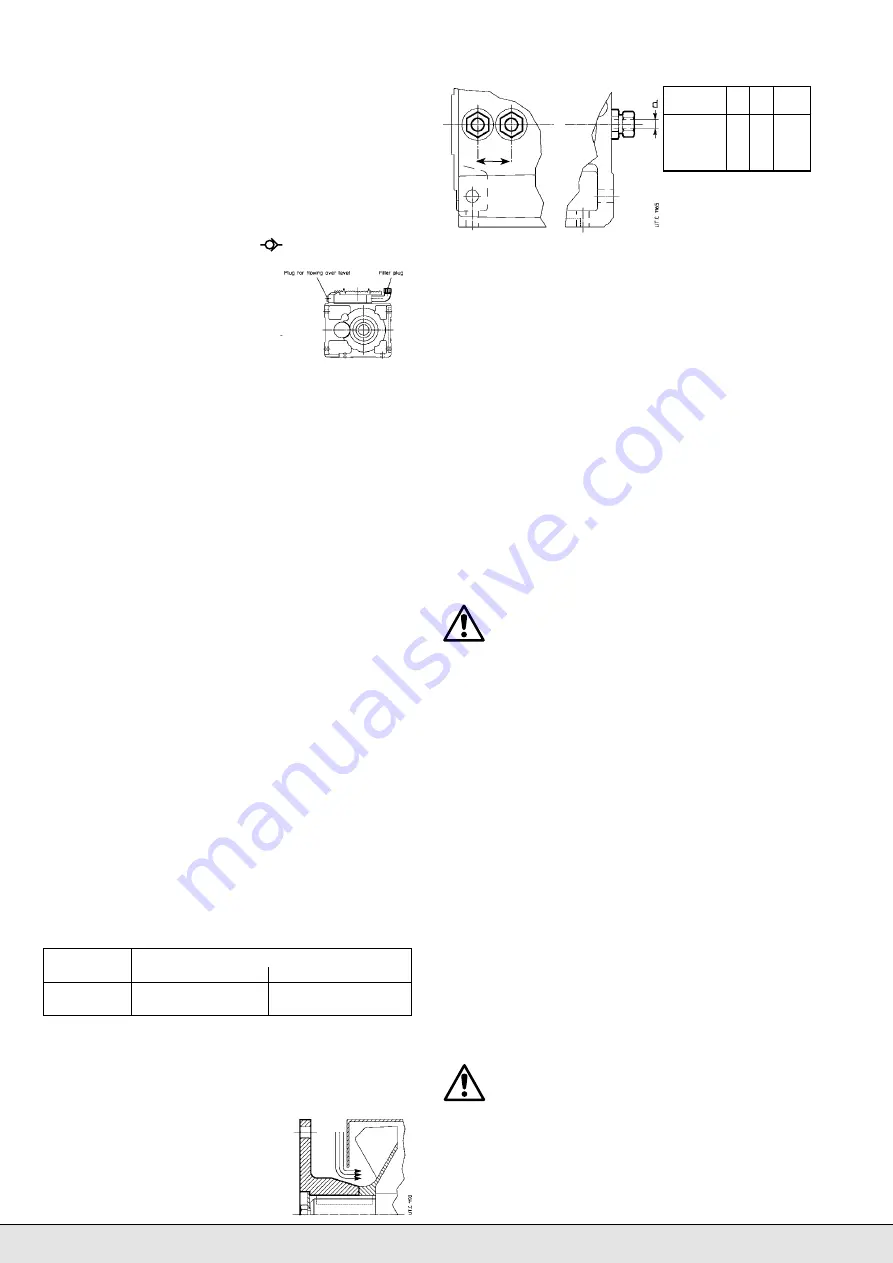

7.2 - Water cooling by coil

The presence of coil is given by water inlets (pipes DIN 2353) protru-

ding from the casing as shown in the following figure.

Attention:

Do not tamper with the eventual stop plate in order to keep

the pipes them locked; in particular keep the pipe locked while tighte-

ning the nut of connection pipe. Water fed into the system must:

– be not too hard;

– be at max tempe20 °C;

– flow at 10

20 dm

3

/min;

– have a pressure 0,2

0,4 MPa (2

4 bar).

Where ambient temperature may be less than 0 °C, make provision

for water drain and compressed air inlet, so as to be able to empty

out the coil completely and avoid freezing up.

When risking high input pressure peaks, install a safety valve set to

a proper operating threshold.

7.3 - Independent cooling unit

See specific documentation supplied together with the unit.

8 - Commissioning

Carry out an overall check, making particularly sure that the gear

reducer is filled with lubricant.

Where star-delta starting is being used, input voltage must match

the motor lower voltage (

connection).

For asynchronous three-phase motor, if the direction of rotation is

not as desired, invert two phases at the terminals.

Before running gear reducers fitted with

backstop device

, make

sure that the

direction of rotation in machine, gear reducer and

motor all correspond correctly.

Attention!

One or more startings in the false direction,

even if short, could irremediably damage the backstop

device, the coupling seats and/or the electric motor.

A

running-in

period is advisable:

– of approx. 400

1 600 h for gear reducers with worm gear pairs

in order to reach maximum efficiency;

– of approx. 200

400 h for gear reducers with bevel and/or cylin-

drical gear pairs in order to reach maximum functionality.

The temperature of both gear reducer and lubricant may well rise

beyond normal values during running-in. After the running-in period it

may be necessary to verify the gear reducer fastening bolt tightness.

Note: worm gear reducer efficiency is lower in the

first running

hours

(about 50) and at every cold starting (efficiency will be better

with oil temperature increasing). For further information consult

ROSSI MOTORIDUTTORI technical catalogues.

9 - Maintenance

9.1 - General

At machine rest, verify at regular intervals (more or less frequently

according to environment and use):

a) all external surfaces are clean and air passages to the gear redu-

cer or gearmotors are free, in order that cooling remains fully

effective;

b) oil level and deterioration degree (check with cold gear reducer at

rest);

c) the correct fastening screws tightening.

During the operation check:

– noise level;

– vibrations;

– seals;

– etc.

Attention!

After a running period, gear reducer (excluding

the shaft mounted gear reducers) is subject to a light inter-

nal overpressure which may cause burning liquid dischar-

ge. Therefore, before loosening whichever plug wait until

gear reducer has become cold; if not possible, take the necessary

protection measures against burning due to warm oil contact. ln all

cases, always proceed with great care.

Maximum oil temperatures indicated in lubrication table (see ch.6.2)

do not represent a hindrance to the gear reducer regular running.

During the oil change, after having unscrewed also the filler plug in

order to improve the discharge, it is recommended to clean inter-

nally the gear reducer casing using the same oil type suitable for the

air

U

T.C

764

Size

d A

1)

spanner

Ø

≈

125 ... 180 12

1

40 22

200 ... 280 12

1

50 22

320 ... 360 16

1

60 30

400 ... 631 16 200 30

A

1) These values for some mounting

positions and designs can vary.

Gear reducer

Lubrication of extruder support

size

Separate lubrication

1)

Joint lubrication

2)

125 ... 451

Filling up

Filling up

to the level (of support) to the level (of gear reducer)

1) Support with metal filler plug with filter and valve, level and draining plug.

2) The level is metal only in the gear reducer casing.