E32.0.02.6C-04

Manual for connection and operation of the

GIA 2000 / AAG and GIR 2002 / AAG

page 10 of 30

4. Configuration of the measuring input

General description and notes to the operating of the menu

By means of

button 1

you can go to the next parameter.

Additionally a given changing in the parameter setting can be confirmed by this button and the new value

will be saved. Afterwards it will be changed to the parameter view again.

By means of

button 2

and

3

you can go from the parameter view to the parameter setting and adjust its

value there.

Hint:

The buttons 2 and 3 are featured with a ‘roll-function‘. When pressing the button once the value will be raised

(button 2) by one or lowered (button 3) by one. When holding the button pressed for longer than 1 sec. the value

starts counting up or down, the counting speed will be raised after a short period of time.

The device also features a ‘overflow-function‘, when reaching the upper limit of the range, the device switches to

the lower limit, vice versa.

By means of

button 4

a

given changing will be cancelled in the parameter setting. The changing will be dis-

carded and the former parameter value will be preserved.

In the parameter view button 4 closes the menu.

Please note:

If you don’t press any button for more than 10 sec. in the parameter setting, the adjustment will

be cancelled, the changing discarded and it will be changed to the parameter view. If you don’t

press any button for more than 60 sec. in the menu, the menu will be automatically closed.

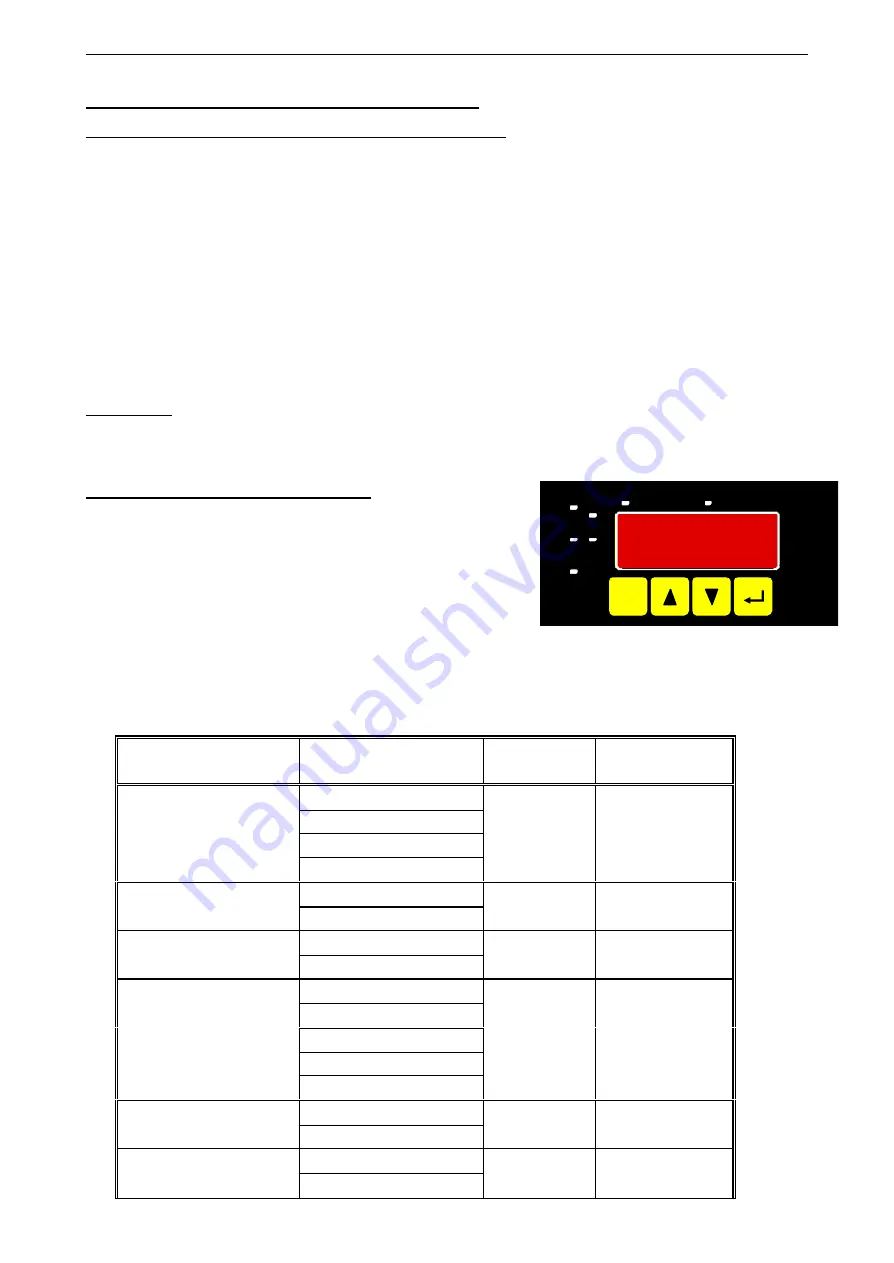

4.1. Selecting an input signal type

-

Turn the device on and wait until it completed its built-in seg-

ment test.

-

At the same time press the pushbutton on the rear side (but-

ton 5) and button 2 for >2 seconds.

The device displays “

InP

“ ('INPUT').

-

Use button 2 or button 3 to select the input signal

(see table below).

-

Validate the selection with button 1. The display will show “

InP

“ again.

Depending on the selected input signal, additional configurations will be needed.

Input type

Signal

to select as

input

proceed in chapter

0 – 10 V

0 – 2 V

0 – 1 V

Voltage signal

0 – 50 mV

U

4.2

4 – 20 mA

Current signal

0 – 20 mA

I

4.2

Pt100

RTD

Pt1000

t.rES

4.3

NiCr-Ni

(type K)

Pt10Rh-Pt

(type S)

NiCrSi-NiSi

(type N)

Fe-CuNi

(type J)

Thermocouples

Cu-CuNi

(type T)

t.tc

4.3

TTL-signal

Frequency

Switch-contact NPN, PNP

FrEq

4.4

TTL-signal

Rotation

Switch-contact NPN, PNP

rPn

4.5

ON/SP

SET

min.

OFF/Hy.

1

2

max.

ALARM

Scale

Analog

CAL

Scale

Analog

CAL

ON/SP

SET

min.

OFF/Hy.

1

2

max.

GIR/GIA

ALARM

SET

1

2

3

4