Safety notes

4

Safety notes

Installing the servos

Always install servos using the vibration-damping

grommets supplied. The rubber grommets provide

some degree of protection from mechanical shocks and

severe vibration.

Installing control linkages

The basic rule is that all linkages should be installed in

such a way that the pushrods move accurately, smooth-

ly and freely. It is particularly important that all servo

output arms can move to their full extent without fouling

or rubbing on anything, or being obstructed mechani-

cally at any point in their travel.It is important that you

should be able to stop your motor at any time. With a

glow motor this is achieved by adjusting the throttle so

that the barrel closes completely when you move the

throttle stick and trim to their end-points.Ensure that no

metal parts are able to rub against each other, e.g. when

controls are operated, when parts rotate, or when motor

vibration affects the model. Metal-to-metal contact cau-

ses electrical „noise“ which can interfere with the correct

working of the receiver.

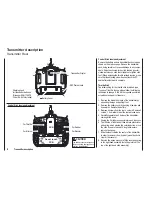

Always extend the transmitter aerial fully before

operating your model.

Transmitter field strength is at a minimum in an imagina-

ry line extending straight out from the transmitter aerial.

It is therefore fundamentally misguided to „point“ the

transmitter aerial at the model with the idea of obtaining

good reception.

When several radio control systems are in use on adja-

cent channels, the pilots should always stand together

in a loose group. Pilots who insist on standing away

from the group endanger their own models as well as

those of the other pilots.

Pre-flight checking

If there are several modellers at the site, check carefully

with all of them that you are the only one on „your“

channel before you switch on your own transmitter.If two

modellers switch on transmitters on the same channel,

the result is interference to one or both models, and the

usual result is at least one wrecked model.

Before

you switch on the receiver, ensure that the thrott-

le stick is at the stop / idle end-point.

Always switch on the transmitter first, and only then

the receiver.

Always switch off the receiver first, and only then

the transmitter.

If you do not keep to this sequence, i.e. if the receiver

is at any time switched on when „its“ transmitter is

switched off, then the receiver is wide open to signals

from other transmitters and any interference, and may

respond. The model could then carry out uncontrolled

movements, which could easily result in personal injury

or damage to property. The servos may run to their

end-stops and damage the gearbox, linkage, control

surface etc. Please take particular care if your model

is fitted with a mechanical gyro: Before you switch your

receiver off, disconnect the power supply to ensure that

the motor cannot run up to high speed accidentally. The

gyro can generate such a high voltage as it runs down

that the receiver picks up apparently valid throttle com-

mands, and the motor could respond by unexpectedly

bursting into life.

Range checking

Before every session check that the system works

properly in every respect, and has adequate range. This

means checking that all the control surfaces respond

correctly and in the appropriate direction to the transmit-

ter commands at a suitable ground range.

Repeat this check with the motor running, while a friend

holds the model securely for you.

Operating your model aircraft, helicopter, boat or car

Never fly directly over spectators or other pilots, and

take care at all times not to endanger people or animals.

Keep well clear of high-tension overhead cables. Never

operate your model boat close to locks and full-size ves-

sels. Model cars should never be run on public streets

or motorways, footpaths, public squares etc.

Checking the transmitter and receiver batteries

It is essential to stop using the radio control system and

recharge the batteries well before they are completely

discharged. In the case of the transmitter this means

- at the very latest - when the message „Battery must

be charged“ appears on the screen, and you hear an

audible warning signal. It is vital to check the state of the

receiver battery at regular intervals. When the battery

is almost flat you may notice the servos running more

slowly, but it is by no means safe to keep flying or run-

ning your model until this happens. Always replace or

recharge the batteries in good time. Keep to the battery

manufacturer’s instructions and don’t leave the batteries

on charge for longer than stated. Do not leave batteries

on charge unsupervised. Never attempt to recharge dry

cells, as they may explode.

Rechargeable batteries should always be recharged

before every session. When charging batteries it is im-

portant to avoid short-circuits. Do this by first connecting

the charge lead banana plugs to the charger, taking

care to maintain correct polarity. Only then connect the

charge lead to the transmitter or receiver battery.