Supplied By www.heating spares.co Tel. 0161 620 6677

20

221679H

7034

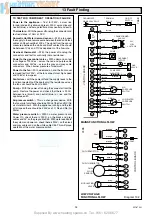

Diagram 10.1

BURNER

PRESSURE TEST

POINT

GAS CONTROL

VALVE

WARNING

230V 50Hz

ELECTRICAL

CONNECTIONS

Please ensure the “Benchmark” logbook is completed and left

with the user.

10.1 Filling Domestic Water Circuit

Check that the boiler is isolated from the electrical supply, at the

external isolator.

Fully open the domestic water supply stop cock or valve in the

supply to the boiler.

Open the domestic water isolation valve, lever in line with the

valve body, see diagram 6.1.

Open all hot water draw-off taps and close them when water

flows. Check for water soundness of the whole domestic water

system and boiler.

10.2 Filling the Heating System

Open the two central heating isolating valves, levers in line with

the valve body, see diagram 6.1.

Flush, fill and vent the system refer to Section 4.8 “Filling

Sealed Systems”.

WARNING. SEVERAL COMPONENTS OPERATE ON MAINS

VOLTAGE AND WITH THE OUTER CASE REMOVED, LIVE

COMPONENTS BECOME EXPOSED.

To assist in filling and venting, the pump may be operated:

Connect the electrical supply, refer to diagram 4 "Instructions

for Use", set button “J” to “winter”, “F” will illuminate, set any

remote heating systems controls, time switch and/or room

thermostat to call for heat.

Note. If the clock/timer kit is to be fitted, refer to the setting

instructions in the Instructions for Use.

Make sure that the automatic air vent is operating correctly.

Take care not to splash any of the electrical components.

Open the controls cover.

Refer to diagram 4 "Instructions for Use". Operate button “J”

between “H” summer and “F” winter to ensure that water flows

through all parts of the boiler and air is not trapped in the boiler

internal bypass.

Pressurise the system until the pressure is 1.5bar (21.5lbf/in2).

Check the heating system and boiler for water soundness.

Check the operation of the safety valve by turning the safety

valve knob in the direction of the arrow.

Lower the pressure to the initial cold fill design pressure, refer

to Table 1. Position the set pointer on the boiler pressure gauge

at this pressure also.

Refit inner case front.

10.3 Preparation for Lighting

Turn on the gas service cock, slot in line with the length of the

cock.

Test for soundness and purge air from the gas supply.

Switch power 'ON' at the mains electrical supply at the external

isolator and switch at the boiler.

Light the pilot refer to relevant parts of "Light the boiler"

(Instructions for Use).

Loosen the burner pressure test point screw and connect a

suitable pressure gauge, see diagram 10.1.

10 Commissioning

10.4 Burner Pressure - Hot Water

Connect the electrical supply it will default to winter, select

summer, the pump will operate for about 30 seconds then the

pump will stop.

Fully open the largest hot water draw off tap whereby the main

burner will light, the flames gradually increasing to the maximum.

Check the soundness of the boiler gas joints, with the main

burner on, using a leak detection fluid. Take care not to splash

any of the electrical components.

To achieve this flow rate a water pressure of at least 0.8bar is

required during commissioning, although subsequently the

appliance will work at a minimum pressure of 0.5bar.

This flow rate should prevent any modulation of the gas pressure.

The burner pressure is factory preset and no adjustment should

be required.

Check the burner pressure is /-0.35mbar (+/-0.14in wg).

of 13.0mbar (5.22in wg). If this is incorrect, the burner pressure

may be adjusted to the correct setting by turning the hot water

gas pressure adjuster (potentiometer), located on the control

board to gain access remove the two screws securing the

controls facia, see diagram 9.1.

Hinge the control facia forward.

Remove the plastic plugs. Using the burner adjusting tool

supplied. (Clockwise to increase), see diagram 10.2. Turn the

adjuster slowly, always making adjustment by reducing below

the required pressure then increasing up to the required setting.

Close the hot water draw off.

If the maximum pressure cannot be obtained, check that the gas

supply is of adequate size, refer to Section 1.7.

10.5 Gas Rate Modulation

The minimum gas rate is factory preset and no adjustment

should be required.

ALWAYS CHECK HOT WATER BURNER PRESSURE FIRST

- REFER TO SECTION 10.4.

To check the minimum gas rate, first make sure that the boiler

is isolated from the electrical supply at the external isolator