Supplied By www.heating spares.co Tel. 0161 620 6677

21

221679H

10 Commissioning

Remove grey wire from the modureg coil (insulate from sheet

metal).

Switch on the electrical supply it will default to winter, select

summer.

Fully open a hot water draw off tap and the main burner will light

at the minimum gas rate.

Check that the burner pressure is 1.2mbar +/-0.2mbar, (0.5in

wg +/-0.1in wg). If this is incorrect, it may be adjusted by

removing the cap and turning the larger adjusting nut of the

modulator, (anticlockwise to decrease the pressure).

If the above adjustment was necessary, it will be essential to

check that the maximum pressure can still be obtained. Push

the spindle gently in to the stop and hold it in. The maximum

pressure should not be less than 14.5mbar, (5.8in wg). If this

pressure cannot be achieved, obtain it by turning the small

adjusting nut, (clockwise to increase the pressure). Always

adjust the minimum pressure first. Reconnect the grey wire and

adjust pressures on potentiometers.

If the maximum pressure is unattainable, check that the gas

supply is of adequate size, refer to Section 1.7 “Gas Supply”.

Put right as necessary.

Isolate the boiler from the electrical supply then reconnect the

modulator cable and refit the cap.

10.6 Domestic Water Flow Rate

This is factory preset and can not be adjusted.

10.7 Burner Pressure - Heating

The burner pressure is factory preset and no adjustment should

be required.

Check that all remote heating system controls, room thermostats,

integral clock and the like are switched on/programmed and

calling for heat.

Set button “J” to “winter” “F”, see diagram 4.

The pump will circulate water through the boiler and the main

burner will light.

Check that the burner pressure, with the heating system cold to

prevent any modulation of the gas pressure, is /-

0.2mbar (+/-0.08in wg) of 7.6mbar (3.05in wg), the central

heating pressure.

If the burner pressure is incorrect, it may be adjusted to the

correct setting by turning the central heating gas pressure

adjuster (potentiometer), located on the control board to gain

access remove the two screws securing the controls facia.

Hinge the control facia open.

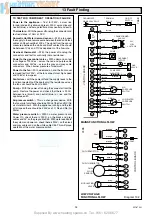

Remove the plastic plugs. Using the burner adjusting tool

supplied (clockwise to increase), see diagram 10.2. Turn the

adjuster slowly, always making adjustment by reducing below

the required pressure then increasing up to the required setting.

Isolate the boiler from the electrical supply.

Remove the pressure gauge and tighten the test point screw.

Test for gas soundness around the burner pressure test point

with the main burner alight, using leak detection fluid. Take care

not to splash any of electrical components.

Replace plastic plugs and refit the control fascia.

10.8 Temperature Settings

The domestic hot water outlet and central heating flow

temperatures are factory preset and sealed, therefore cannot

be adjusted.

The nominal temperature setting for the domestic hot water

outlet is 65

o

C (149

o

F) at a flow rate of 3.6Litre/min (0.8gall/min).

The nominal maximum flow temperature setting for central

heating is 82

o

C (180

o

F).

10.9 Heating System - Commissioning

Check that all remote controls and integral clock are calling for

heat.

Fully open all radiator valves.

Set the heating system in operation and balance the radiators.

Refer to Section 4.6 and diagram 4.1.

Allow the system to reach maximum temperature then switch

off, isolate the boiler from the electrical supply and drain the

system rapidly whilst still hot.

Remove the inner case front.

Fill and vent the system as described in Section 10.2 “Filling the

Central Heating Circuit”. Add inhibitor, if applicable, refer to

Section 4.9 “Corrosion Inhibitor”.

Lower the pressure to the initial cold fill design pressure, using

the external draining tap, close to the boiler, refer to Table 1 and

Section 4.10.

10.10 Completion

Refit the inner case front.

Fit the side panels, hook into the threaded lugs at the top, see

diagram 10.3.

Fit the case base, slide back engage the rear lugs, secure with

two screws supplied, see diagram 10.4.

Secure the side panels at the bottom with the four screws, see

diagram 10.3.

Fit the outer case front by locating it on one side then wrap it

7078

Diagram 10.2

CABLE ENTRY

COVER

CLOCK-TIMER

COVER

CONTROL

BOARD

COVER

BURNER PRESSURE

ADJUSTING TOOL

DOMESTIC HOT WATER BURNER

PRESSURE POTENTIOMETER

HEATING BURNER

PRESSURE

POTENTIOMETER

PLASTIC

PLUG (2)

CONTROL

BOARD

COVER

SECURING

SCREW (4)