MO003-GB 18/05/06

Operative Manual

Rev.0

Page 21 of 34

Chapter 4 – Using the apparatus

4.1 Description of the apparatus

The SATURNO scialytic wall lamp consists of an optical unit (superficially vacuum treated reflecting

paraboloid in glass, lamp-holder and one bulb with main functions, upper closure dome in aluminium and

lower in tempered glass, external joining ring in aluminium too between the lower glass and upper cap

cover and electric cabling). A semi rounded section aluminium fork starts from a reflector that with

terminal joints in aluminium allows rotation along the 330° axis. An oscillating arm in aluminium is

attached to the semi fork whose weight applied to the reflector is countered by the action of the internal

spring that works by compression.

The oscillating arm is inserted into the horizontal arm in aluminium and fixed mechanically with a stop

sieger that allows complete 360° rotation without limit electrically through a male and female connector

using two teflon bearings. At its extremity there is the command panel that allows turning the lamp on

and off and adjusting the luminous intensity. The horizontal arm is in its turn connected centrally to a

tube join to a flange in aluminium with four holes that allow its rigid anchorage to the wall with Fischers

or other solutions. The continuous mechanical rotation is allowed by two other teflon bearings steel pin

in opportune section, fixed rigidly to the aluminium plate with a threaded steel block internally and two

anchorage screws to the plate. The transformation of the tension from power tension to extremely low

tension takes place in electro-mechanical transformers positioned in the technical unit or the immediate

vicinity of the device.

The parabolic reflector is characterised by always being in focus from a minimum distance of 60 cm to a

distance of 200 cm.

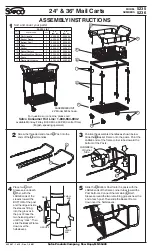

1 Wall plate

2 Electric board

3 Horizontal arm

4 Control panel 1/0

5 Vertical arm

6 Semi fork

7 Upper cap cover

8 Sterilised handle

9 Protective glass

,

The presence of electro-scalpels, defibrillators and other devices functioning at high

frequence can be the cause of disturbance to the scialytic lamp. Their influence will be

shown by possible variations in luminous intensity.

9

Summary of Contents for SATURNO WALL

Page 30: ...MO003 GB 18 05 06 Operative Manual Rev 0 Page 30 of 34 6 2 Explode drawing...

Page 31: ...MO003 GB 18 05 06 Operative Manual Rev 0 Page 31 of 34...

Page 32: ...MO003 GB 18 05 06 Operative Manual Rev 0 Page 32 of 34...

Page 33: ...MO003 GB 18 05 06 Operative Manual Rev 0 Page 33 of 34...

Page 34: ...MO003 GB 18 05 06 Operative Manual Rev 0 Page 34 of 34...