Loading Paper

65

2

2000-sheet Large Capacity Tray

Important

❒

The 2000-sheet Large Capacity Tray is set to 11"

×

8

1

/

2

"

K

at factory default.

❒

If you want to load the A4 paper in the 2000-sheet Large Capacity Tray (op-

tional), contact your sales or service representative.

A

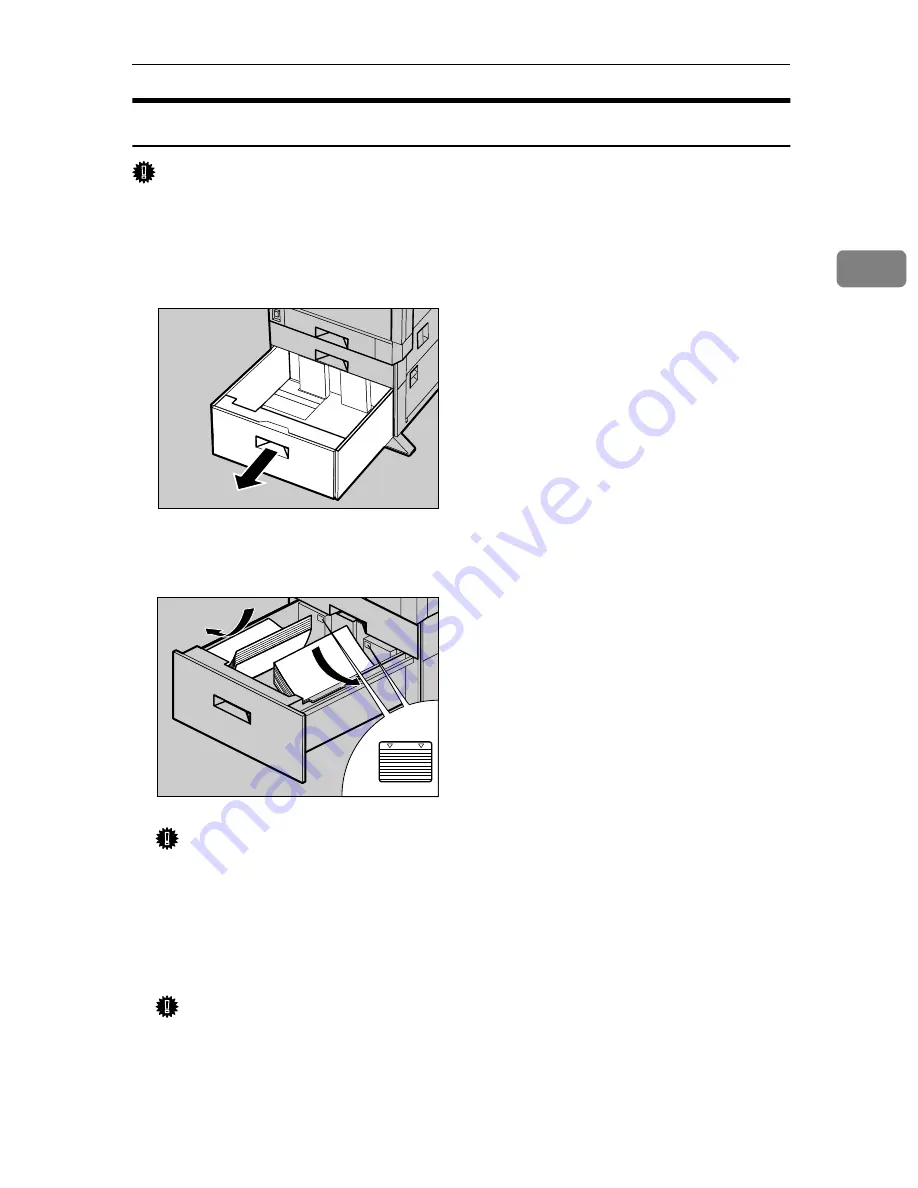

Slide the paper tray out slowly until it stops.

B

Align all four sides of the paper stack, and then load two stacks next to each

other.

Important

❒

Be sure to align the paper and load them against the left and right walls, or

it could result in a paper misfeed.

❒

Confirm that the top of the stack is not higher than the Limit mark inside

the tray.

C

Slide the paper tray back slowly until it stops.

Important

❒

Do not forcefully slide in the paper tray. This may skew the paper stack

and cause misfeeds.

ZDJY008J

ZDJY009J