GEAX

s.r.l.

Chapter 2

DRILLING MACHINE SCHEDULED MAINTENANCE

2-4

2.2.2

Operations relating to the replacement of lubrication / hydraulic oils

First of all:

•

operate when the components are not hot;

•

provide a container to collect the lubricant drained from the machine and

for any leakage during the loading stage;

•

wear impermeable gloves;

•

work in a ventilated area;

•

bear in mind that used lubricant is toxic therefore handle with care and

rinse immediately with soap and water if it comes into contact with eyes or

parts of the body;

•

work in absence of open flames;

2.2.3

Winch gear unit scheduled lubrication operations

The lubricant of the winch gear unit must be replaced at a frequency shown in

tab. 2.2.3.1-2

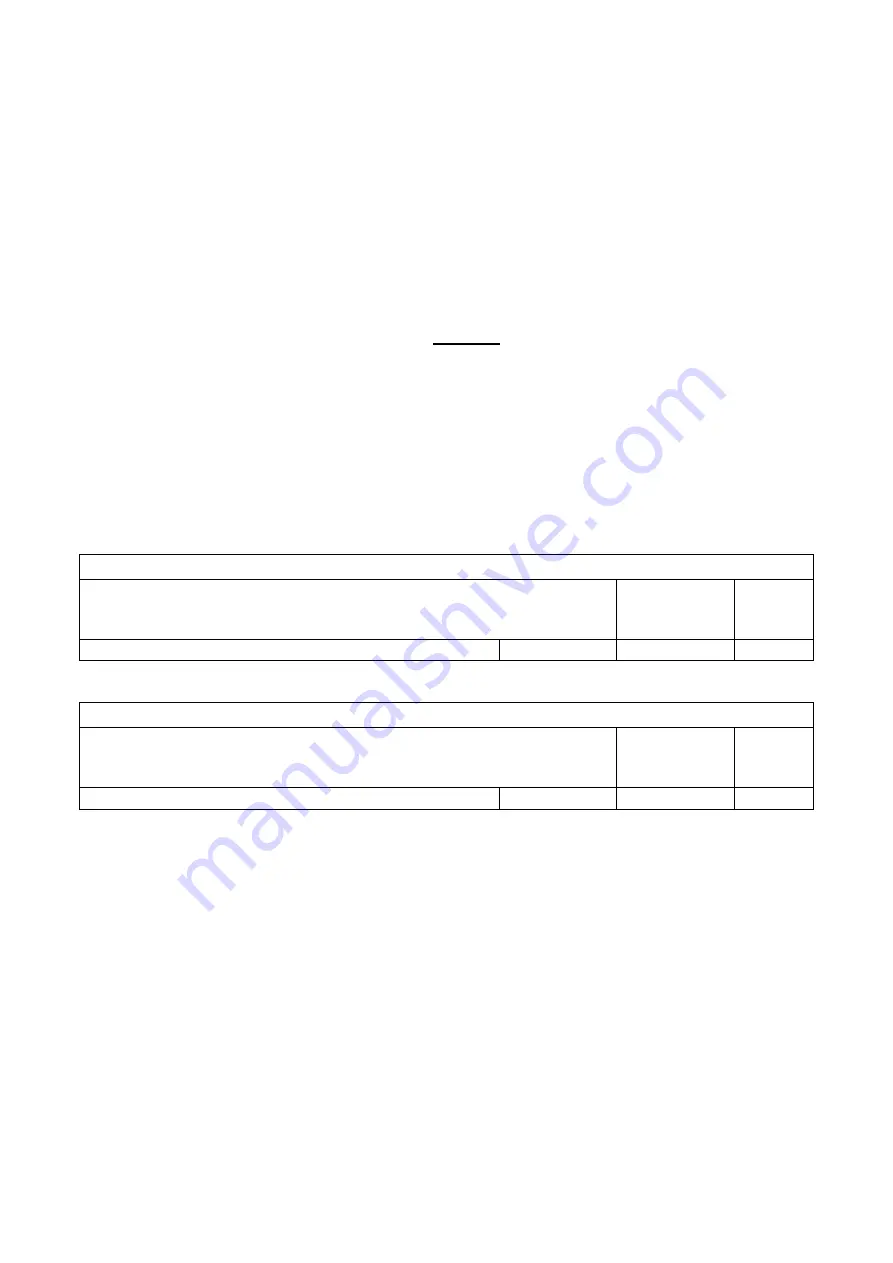

MAIN WINCH GEAR UNIT LUBRICATION

Brevini BWF 2000

LUBRICATION DESCRIPTION

Replacement

frequency

[hours]

Quantity

[c.c]

AGIP ROTRA MP 80W-90

API GL5

2000

350

tab. 2.2.3.1

AUXILIARY WINCH GEAR UNIT LUBRICATION

Brevini DW 090

LUBRICATION DESCRIPTION

Replacement

frequency

[hours]

Quantity

[c.c]

AGIP ROTRA MP 80W-90

API GL5

4000

150

tab. 2.2.3.2

Alternatively one can consult the manufacturer manual to find equivalent lubricant

producers

2.2.4

Hydraulic circuit oil periodic replacement

For this operation refer to the manual of the JCB excavator.

2.2.5

Periodic replacement of the internal combustion engine lubricant

For this operation refer to the manual of the JCB excavator.

Summary of Contents for XD5

Page 1: ...MAINTENANCE MANUAL Rev 01 17 GEAX s r l XD5...

Page 20: ...GEAX s r l Chapter 3 MAINTENANCE ACCORDING TO THE CONDITIONS OF THE DRILLING M 3 3...

Page 21: ...GEAX s r l Chapter 3 MAINTENANCE ACCORDING TO THE CONDITIONS OF THE DRILLING M 3 4...

Page 22: ...GEAX s r l Chapter 3 MAINTENANCE ACCORDING TO THE CONDITIONS OF THE DRILLING M 3 5...