GEAX

s.r.l.

Chapter 2

DRILLING MACHINE SCHEDULED MAINTENANCE

2-5

2.2.6

Management of all waste fluids drained from the machine

Such fluids cannot be disposed of in the environment and should be taken to

waste collection centres in compliance with the regulations in force in the

country where the machine operates.

2.3 Scheduled checks on ropes and pulleys

2.3.1

Visual inspection of ropes

The machine is equipped with two winches and relative ropes:

•

the main winch for telescopic Kelly bar sliding;

•

the auxiliary winch for lifting the machine accessories or elements related to

making the hole;

The tables below illustrate the frequency and methods for checking

the ropes.

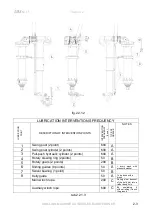

Main winch rope inspection

Diameter 9 mm

Operation

Frequency

[hours]

Diameter

[mm]

Visual inspection with the mast in transport position of the

section of rope from the winch to the swivel and rope terminal.

This last part can get damaged more easily in the event of

operating abnormalities of the swivel.

at the

beginning

of each

work shift

Inspection of the entire rope while making a hole; when the hole

has been completed, one must check the descent of the Kelly

bar into the hole at low speed, inspecting the rope closely during

the rotation of the winch drum.

If one finds worn points measure the diameter,

with the engine

off

, (it must not fall below more than 7% of the nominal value);

200

>8.4

If one finds anomalies in shape or broken wires, refer to paragraph 3.2.1

tab.2.3.1.1

Summary of Contents for XD5

Page 1: ...MAINTENANCE MANUAL Rev 01 17 GEAX s r l XD5...

Page 20: ...GEAX s r l Chapter 3 MAINTENANCE ACCORDING TO THE CONDITIONS OF THE DRILLING M 3 3...

Page 21: ...GEAX s r l Chapter 3 MAINTENANCE ACCORDING TO THE CONDITIONS OF THE DRILLING M 3 4...

Page 22: ...GEAX s r l Chapter 3 MAINTENANCE ACCORDING TO THE CONDITIONS OF THE DRILLING M 3 5...