4.6.2 S-Tronic Plus / S-Tronic Lambda control

Power connection

❒ Run the cable of the flue gas temperature sensor, boiler sensor, induced draught,

STL, display and door switch to the controller and connect the wiring in accord‐

ance with the operating instructions of the boiler control

➥ Tuck any extra cable into the cable duct

❒ Run the cable of the broadband probe, servo-motors, flue gas temperature sensor,

boiler sensor, induced draught, STL, display and door switch to the controller and

connect the wiring in accordance with the operating instructions of the boiler con‐

trol

➥ Tuck any extra cable into the cable duct

❒ Connect the components according to the power connection diagram

➥ The flexible sheathed cable must be used for the wiring; this must be of the

correct size to comply with applicable regional standards and regulations!

Once the individual components have been wired:

❒ Wire the mains connection in the controller box

➥ The power supply line (mains connection) must be fitted with a max. C13A fuse

by the customer!

➥ Observe the circuit diagrams in the boiler controller operating instructions.

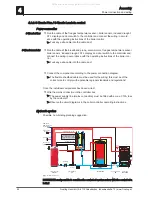

Hydraulic system

Possible, non-binding planning suggestion:

M

M

M

M

Room sensor

(Option)

External sensor

Mains supply

230V

Log wood boiler

S3 Turbo

Pump assembly

FE

Pump 1

Flow temp. sensor 1/2

Heating circuit 1/2

Mot. mixing valve 1/2

Layered tank

Domestic

hot water

HKP 0

Cold

water

Pump assembly

OE

DHW tank

Unicell NT-S

Note:

Controller S-Tronic Plus

Temp. sensor 0.1

Temp. sensor 0.2

Return sensor

With heating circuit modules

(Bus connection) up to

heating circuits are available

18

RBG 3200 /

RBG 3200 Touch

(Option)

Balancing

valve

NOTICE! It is not possible to combine the control of a return mixer with the control of a

boiler!

S-Tronic Plus:

S-Tronic Lambda:

4

Assembly

Power connection and wiring

58

Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

All manuals and user guides at all-guides.com