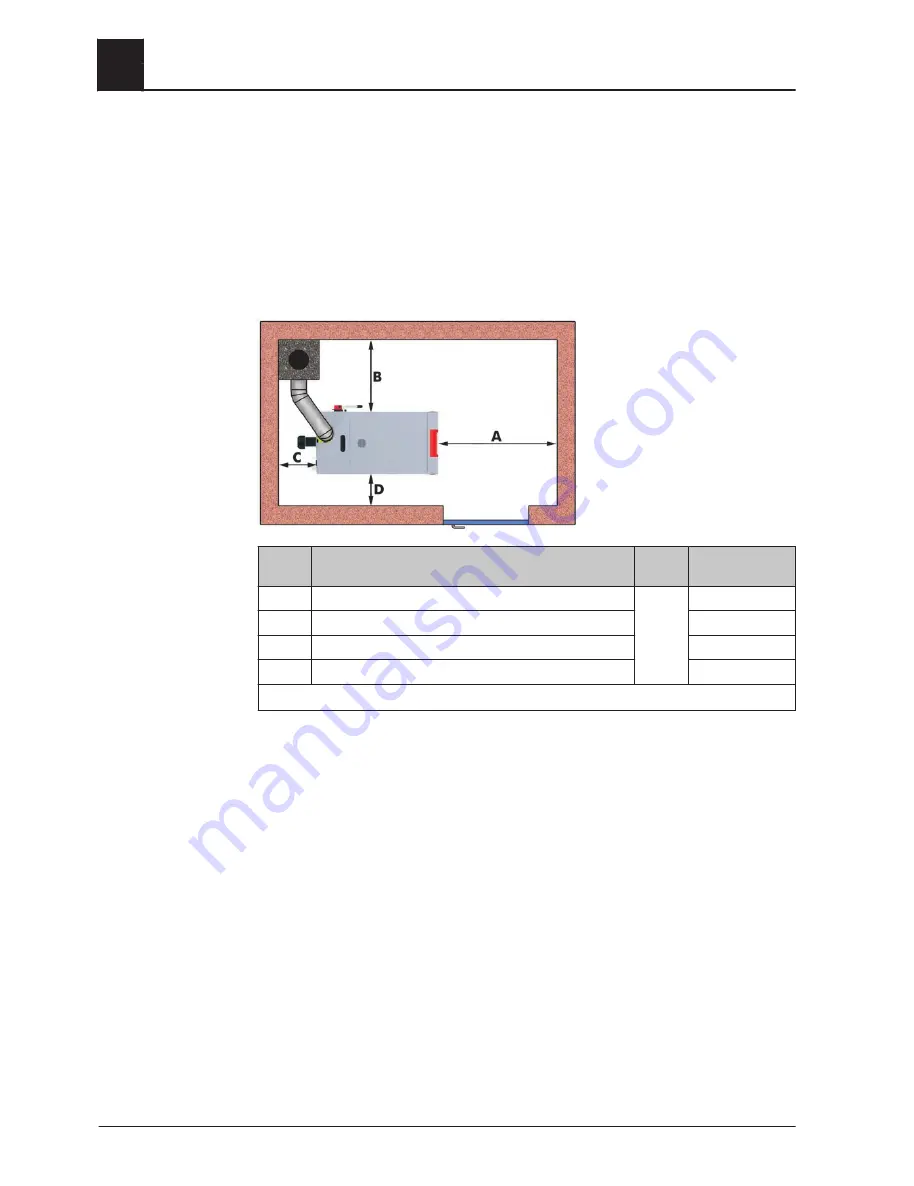

4.3.3 Minimum distances in the boiler room

▪ The system should generally be set up so that it is accessible from all sides allow‐

ing quick and easy maintenance.

▪ Regional regulations regarding necessary maintenance areas for inspecting the

chimney should be observed in addition to the specified minimum distances!

▪ Observe the applicable standards and regulations when setting up the system.

▪ Observe additional standards for noise protection

(ÖNORM H 5190 - Noise protection measures)

Dimen‐

sion

Description

Unit

S3 Turbo

A

Distance - front of boiler to wall

mm

800

B

Distance – side of boiler to wall

800 (200)

1)

C

Distance – back to wall

500

D

Distance – side of boiler to wall

200 (800)

1)

1.The side of the boiler where the WOS lever is located (B or D) should be at least 800 mm from the wall to allow easy access for connecting

the appliance and for maintenance work (e.g. induced draught).

4.4 Before Installation

4.4.1 Changing door stops (as needed)

The boiler comes with the door stop on the right. To change the side the door stops

are on, proceed as follows.

Changing the stop of the combustion chamber door

The following example shows how to change the door stop on the combustion cham‐

ber door. The procedure is the same for changing the stop on the fuel loading door

and pre-heating chamber door!

❒ Open the combustion chamber door

4

Assembly

Setting up in the boiler room

22

Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

All manuals and user guides at all-guides.com