25

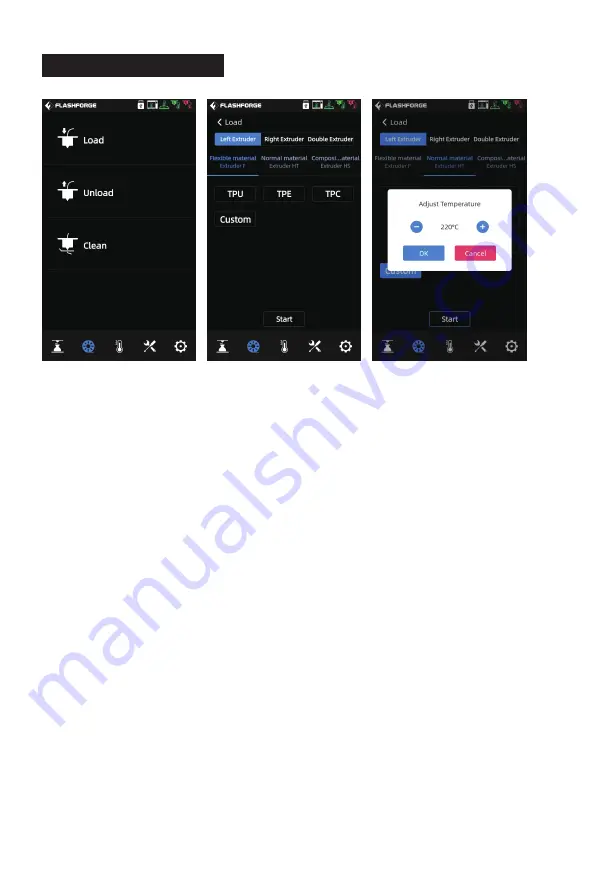

6.2 Filament Screen

The filament screen includes: [Load], [Unload] and [Clean].

·

·

During filament feeding and withdrawing, users can set according to the

filament to be actually installed. If the currently required filament is not in the

screen, users can customize the filament and set the required temperature for

filament feeding.

Filament cleaning: When the filaments printed in the last two times are different,

please perform filament cleaning. In this way, it will avoid the situation that the

filament is carbonized thus causing blockage or is not extruded due to different

melting temperatures of the filaments. When switching from a high-temperature

filament to a low-temperature filament, this operation must be performed; For

example, when you need to switch it to PLA material after printing with PC

material, it is necessary to clean the PC material from the nozzle, so it is

necessary to set the temperature required for melting the PC material until all the

PC material is extruded from the nozzle and there is no residue left in the nozzle.