59

HNC3 825 / HNC3 825 perform

Maintenance

3.

Clean lubricating nipple.

4.

Place the pressure grease gun onto the nipple and pump 3 times.

🡆

A small amount of lubrication will come out of the seals.

5.

Repeat the process for all four lubricating nipples.

6.

Switch machine on.

7.

Move several times over the entire length of the axle to distribute the grease.

🡆

Axis is covered with a thin film of grease.

10.3 Check / replace the drive belt

The drive belts are wear and tear parts and must be checked regularly. The belt

tension must be checked regularly. If the belt tension is too high or too slack, it

could lead to damage on the machine.

Drive belt Y-axis

Personnel:

●

Trained machine operator

Protective equipment:

●

Protective clothing

●

Protective gloves

●

Protective footwear

●

Safety goggles

1.

Switch off the machine at the main switch, disconnect the power supply.

1

2

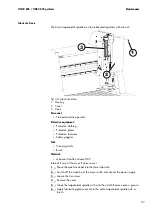

Fig. 38: Remove the cover

1 Remove the cover screws

2 Cover

2.

Remove five screws from the right cover.

Summary of Contents for Hammer HNC3 825

Page 69: ......