Chapter 2 - page 9

MCO-TCO work mode

2.4.3 CONTINUOUS JOG

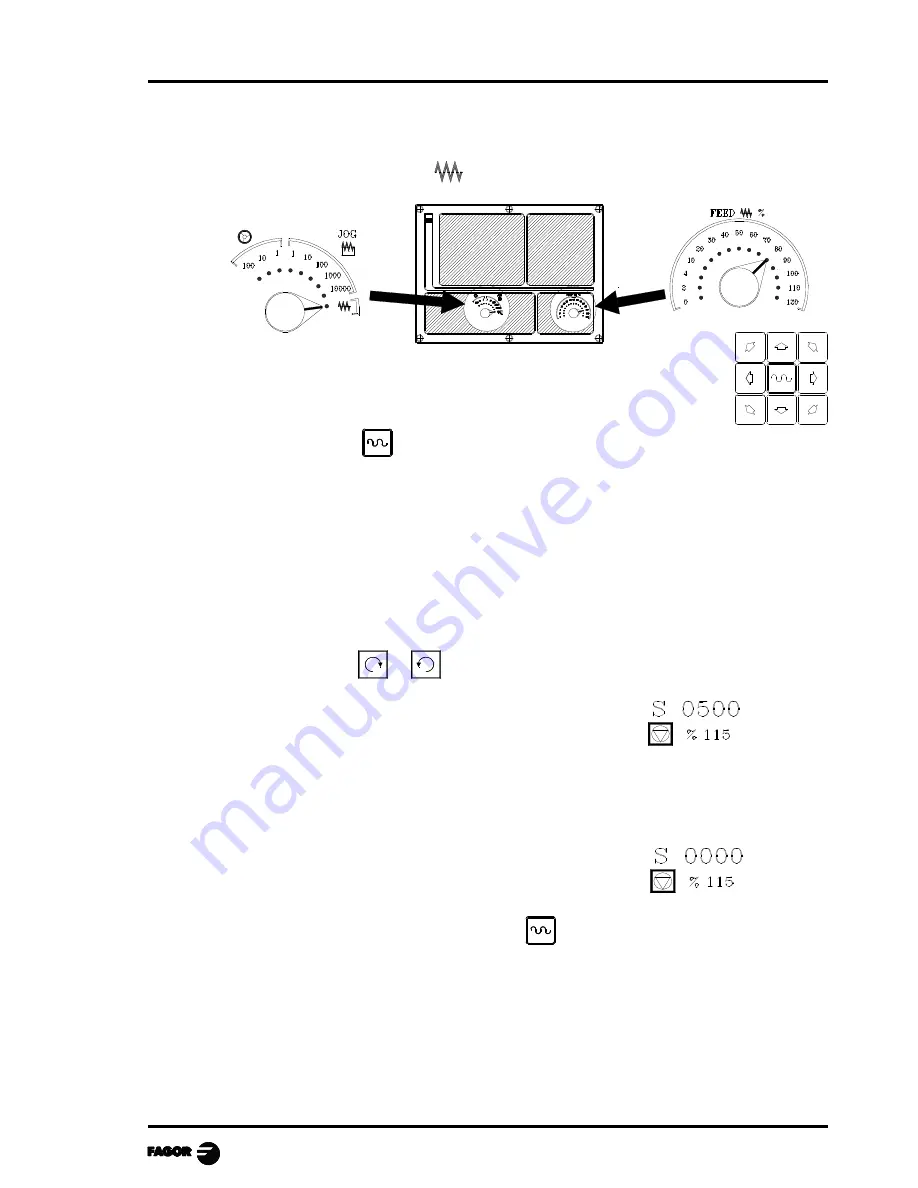

Place the left-hand switch in position

and on the right-hand switch select the percentage (0%

to 120%) of the feedrate selected to be applied.

Continuous movement should be done axis to axis. To do this press the JOG

key for the direction of the axis to be moved.

The axis moves with a feedrate equal to the percentage (0% to 120%) of the «F»

feedrate selected.

If during movement the key

is pressed the maximum feedrate possible is carried out, as is stated

in the “G00FEED” axis machine parameter. This feedrate will be applied as long as said key is

pressed, and when released the previous feedrate will be resumed.

Depending on the value assigned to general logic input “LACOHM”, the movement will be made

in one of the following ways:

* The axis will only move while the relevant JOG key is pressed.

* The axis will start moving when the JOG key is pressed and will not stop until said JOG key

or another JOG key is pressed again, and in this case the movement is transferred to what is

indicated by the next key pressed.

When operating with feedrate "F" in millimeters/revolution the following cases may arise:

a)

The spindle is started.

or

The CNC moves the axes to the F programmed.

b)

The spindle is stopped but there is a spindle speed S selected.

Feature available at the TCO model when working with G95.

The CNC calculates the feedrate in millimeters/minute corresponding to the theoretical "S" and

moves the axis.

For example, if «F 2.000» and «S 500»:

Feedrate = F (mm/rev.) x S (rev/min)= 2 x 500 = 1000 mm/min

The axis moves at a feedrate of 1000 in millimeters/minute.

c)

The spindle is stationary and there is no spindle speed S selected.

Feature available at the TCO model when working with G95.

The axes will only move in rapid and only if the

key and the relevant axis key are pressed.