WorkForce 1100/Epson Stylus Office T1110/B1100/T1100/Epson ME Office 1100

Revision C

Adjustment

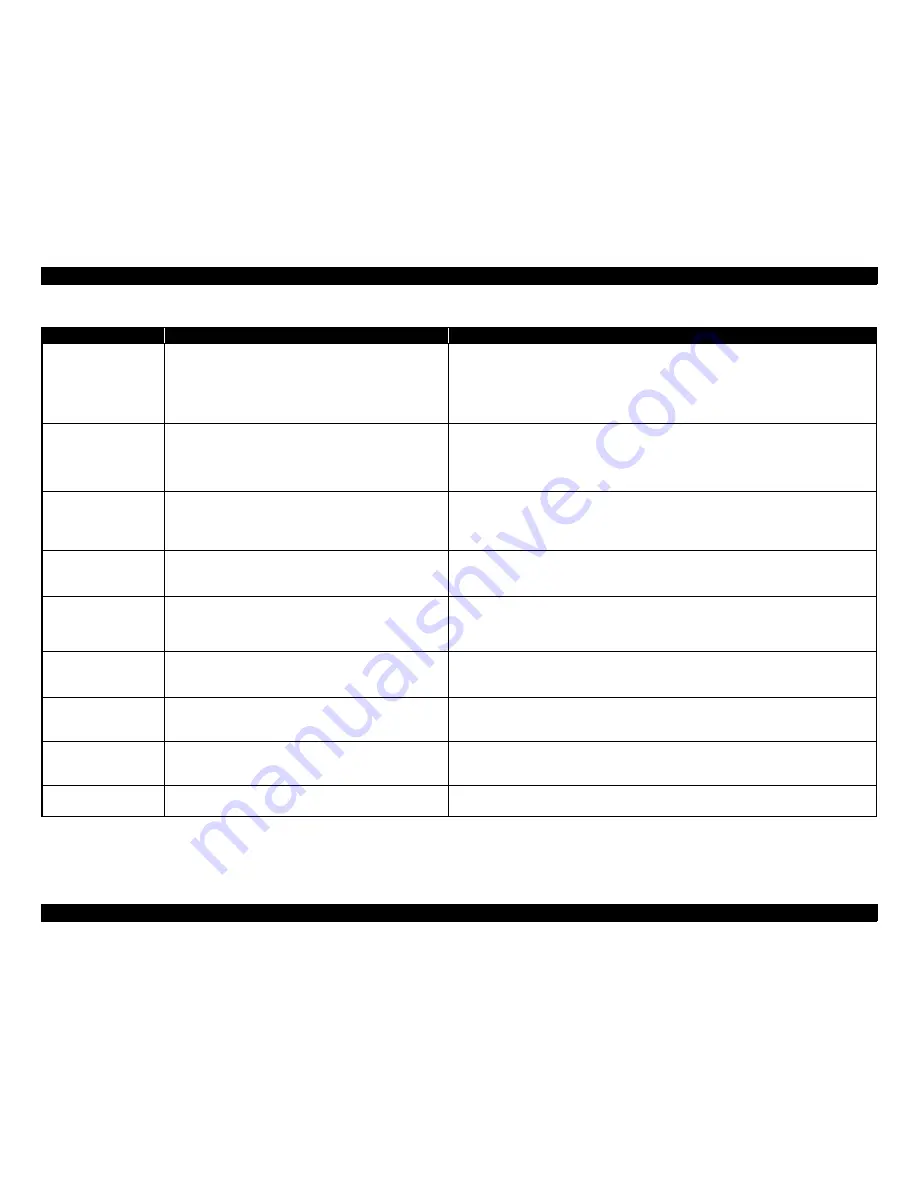

Adjustment Items and Overview

130

Confidential

Initialize PF

deterioration offset

The deterioration amount of the PF Roller Shaft is reflected to

the paper feed correction amount. Every time a sheet of paper is

fed, the deterioration amount is counted on the basis of the

original counter value setting.When the PF Roller Shaft or

Printer Mechanism has been replaced during repair, the PF

deterioration counter must be reset.

1. Select and execute this function in the Adjustment Program.

2. Reset the PF deterioration counter.

Disenable PF

deterioration offset

The PF deterioration compensation counter can be reset only

when the PF Roller Shaft is new. To reduce the ancillary work in

servicing, enter the maximum value (value for which

deterioration compensation is not made) if the PF Roller Shaft

has not been replaced.

1. Select and execute this function in the Adjustment Program.

2. Reset the PF deterioration counter.

First dot position

adjustment

This function adjusts the print starting position in the CR main

scanning direction.

1. Select this function in the Adjustment Program and print the adjustment pattern.

2. Enter the value whose printed lines meet the adjustment pattern exactly 5 mm away from the left

edge.

3. The correction value is saved to the specific EEPROM address of the Main Board.

PW adjustment

This adjustment is made to correct the PW Sensor mounting

position on a software basis to improve a paper detection error

caused by the variation of the mounting position.

1. Select this function in the Adjustment Program and print the adjustment pattern.

2. Select a pattern number 5mm away from each edge, and enter that number in the program.

3. The correction value is saved to the specific EEPROM address of the Main Board.

Head angular adjustment

This adjustment is made to correct the error in the Print Head

mounting position (Head angle) to make the nozzle line straight

with respect to the paper feeding direction. Angular

displacement is also checked for.

1. Select this function in the Adjustment Program and print the adjustment pattern.

2. After checking the displacement amount of the pattern, enter the pattern number which has the

smallest amount of displacement.

Bi-D adjustment

This adjustment is made to correct the print timing in the go and

return paths in bi-directional printing.

1. Select and execute this function in the Adjustment Program.

2. Pattern printing and adjustment are automatically executed.

Supplement: Be sure to confirm that there are no dots missing before executing this adjustment.

BAND printing

adjustment

This adjustment is made to correct the mis-alignment of vertical

lines and timing of printing at monochrome draft printing.

1. Select and execute this function in the Adjustment Program.

2. Pattern printing and select the adjustment value, and write it to the specific EEPROM address on

the Main Board.

PF adjustment

This correction is made when the actual paper feed amount

differs greatly from the theoretical value due to paper slip, PF

roller tolerances, etc. during paper feed for printing.

1. Select this function in the Adjustment Program and print the adjustment pattern.

2. Select or measure the adjustment value, and write it to the specific EEPROM address on the

Main Board.

PF band adjustment

This corrects variations in paper feed accuracy in the band print

mode to achieve higher print quality.

1. Select this function in the Adjustment Program and print the adjustment pattern.

2. Select the adjustment value, and write it to the specific EEPROM address on the Main Board.

Table 5-1. Adjustment Items

Adjustment

Purpose

Method Outline

Summary of Contents for WorkForce 1100

Page 8: ...Confidential C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 21: ...Confidential C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 29: ...Confidential C H A P T E R 3 TROUBLESHOOTING ...

Page 61: ...Confidential C H A P T E R 4 DISASSEMBLYANDASSEMBLY ...

Page 128: ...Confidential C H A P T E R 5 ADJUSTMENT ...

Page 152: ...Confidential C H A P T E R 6 MAINTENANCE ...