4.4.2 Pump Outlet Tubing Installation – Ceiling or Wall Mounted Furnace (skip if

you have a tank mounted furnace)

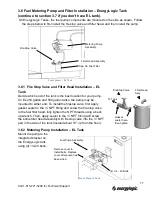

If installing the furnace with a remote tank, the required fuel discharge tubing is not included.

The tubing is installed with the same procedure as in Section 4.4.1, except for tube routing.

The following guidelines are provided:

Pump Discharge Tubing Considerations:

•

Use 3/8” O.D. copper tubing, with 1/32” wall thickness.

•

The discharge line must have an upward slope towards the preheater, with no loops or

high points to trap air. Run it as straight as possible.

•

If high points are unavoidable, install high-point-bleed kits (available accessory)

wherever the discharge line routing steps down to provide a means to bleed trapped air

in the line during priming.

•

Use 45° flare connections for copper tube. Never use compression fittings.

•

Maximum vertical run of discharge tubing is 30 feet.

•

Maximum total run of discharge tubing is 150 feet.

•

Discharge line from the metering pump must be run indoors, with a minimum ambient

temperature of 50°F (10°C).

•

Installation of a shut-off valve after the fuel pump will make routine maintenance easier.

It will prevent loss of oil in the discharge line if the pump discharge connection is to be

loosened for priming or other maintenance.

•

The use of a remote system gauge kit (available accessory) is recommended in order to

have convenient pressure readings available at the burner.

25

Call 1-615-471-5290 for Technical Support

Summary of Contents for EL-140H

Page 2: ......

Page 51: ...45 Call 1 615 471 5290 for Technical Support ...

Page 90: ...10 2 Carlin 50200E Primary Control 84 Call 1 615 471 5290 for Technical Support ...

Page 91: ...85 Call 1 615 471 5290 for Technical Support ...

Page 93: ...87 Call 1 615 471 5290 for Technical Support ...

Page 94: ...88 Call 1 615 471 5290 for Technical Support ...

Page 95: ...89 Call 1 615 471 5290 for Technical Support ...