5 – 7

Section 5 • Maintenance/Service

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

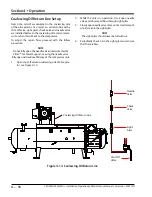

Compressor Unit Leak Check After

Servicing

The compressor unit must be checked for leaks after

servicing to ensure a tight system. For additional leak

testing information, refer to Chapter VI of ASME B31.3

Process Piping Code.

CAUTION

Do not hydro test compressor unit. Failure to comply

may result in damage to equipment.

1. If servicing the compressor unit was completed,

proceed to step 2. Otherwise, isolate the compres-

sor unit from the house system, see Compressor

Unit Isolation procedure.

2. Open all shut-off valves, check valves, control valves

and solenoid valves in the system to be tested.

3. Slowly pressurize compressor unit through suction

oil charging port with dry nitrogen.

4. Using appropriate soap solution, check for leaks on

joints and connections of the serviced component.

5.

If leaks are found, depressurize system and fix leaks.

Repeat steps 3 and 4 until all leaks are fixed.

6. Evacuate from suction oil charging port.

7. Close all valves previously opened in the system.

Remove tags as per the local lock-out/tag-out

procedure.

8. Turn the motor and oil pump disconnect switches

to the ON position.

9. Return compressor unit to service. Oil System

Components

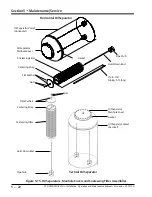

Oil System Components

Oil Sampling

WARNING

When working with LFG, NG or other dangerous

or fl ammable gases, ensure there are adequate

ventilation and vapor detectors. Refer to national fi re

and building codes. Failure to comply may result in

serious injury or death.

WARNING

Improper selection or application of fl uid diagnostic

products can cause serious injury or damage. The

user is solely responsible for making the fi nal

selection of products to ensure that the overall system

performance and safety requirements are met. These

include reviewing fl uid compatibility with materials

and seals.

WARNING

Avoid skin contact with any condensate or oil. Wear

rubber gloves and a face shield when working with

condensate or oil. Failure to comply may result in

serious injury or death.

DANGER

Sampling often releases hot fl uid under high

velocity/pressure.

1.

Hot fl uid can cause severe burn injuries.

2.

Skin penetration from high-pressure fl uid

can occur, causing severe injury, gangrene

and/or death. If this happens, immediate-

ly contact an experienced medical practi-

tioner.

3.

Hot fl uid escaping to the atmosphere can

ignite if it comes into contact with an igni-

tion source. This can lead to severe property

damage.

Recommendations:

1. Make sure you´re aware of the risks associated with

the fluid being sampled or worked with. Check with

the manufacturer.

2. If you have not been trained to sample, service, re-

pair, or troubleshoot a pressurized fluid system,

especially a hydraulic system, you are at risk of suf-

fering an accident. Seek the proper training before

proceeding.

Summary of Contents for Vilter VSH

Page 2: ......

Page 30: ...2 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 54: ...3 24 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 74: ...4 20 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 144: ...5 70 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 156: ...7 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 158: ...8 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 204: ...8 48 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 206: ...A 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 210: ...B 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 216: ...C 6 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 219: ......

Page 221: ......

Page 224: ......

Page 225: ......

Page 226: ......

Page 242: ...E 12 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 248: ...G 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 249: ......