5 – 39

Section 5 • Maintenance/Service

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

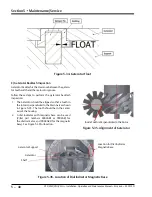

Table 5-12. Gaterotor Float

Model

Float

in. (mm)

VSM-97 - VSM127

0.045 (1.143)

VSM 71 - VSM 401

0.045 (1.143)

VSM 501 - 701

0.045 (1.143)

VSS/VSSH 291 - 601

0.045 (1.143)

VSS 751 - 901

0.055 (1.397)

VSS/VSH 791 - 1301

0.060 (1.524)

VSS 1501 - 2101

0.060 (1.524)

VSS 2401-3001

0.060 (1.524)

4. If it is easy to pull out the feeler gauge, then increase

the feeler gauge thickness by 0.001” and repeat

above steps 1-3. If it is slightly tight to pull it out,

then the clearance corresponds to the feeler gauge

thickness.

NOTE

Replacement gaterotors are the same dimensionally as

the gaterotors installed at the factory. Therefore, the

same shims can be reused when replacement is needed

to preserve the 0.003” – 0.004” clearance.

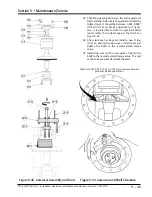

B) Gaterotor Float Measurement

1.

Before doing any measurements, first conduct a vi

-

sual check to see if there is any noticeable clearance

between the gaterotor and its bushing, see Figure

5-32. If there is noticeable clearance, please contact

Vilter Service Department.

NOTE

The number of bushings on a gaterotor can be anywhere

from one to three.

2.

To measure the float between the gaterotor bush

-

ing and the support damper pin (see Figure 5-34),

position a dial indicator at the tip of the support as

shown in Figure 5-33. Hold the gaterotor in place,

then gently move the support teeth back and forth

with two fingers (and record measurement). Refer to

Table 5-12 to find the maximum float value.

NOTICE

If clearance measurements are out of tolerance,

contact Vilter Service Department for further

assistance.

Figure 5-32. Visual Inspection Between

Gaterotor and Bushing

Figure 5-33. Gaterotor Float Dial Location

Dial Indicator

Gaterotor

Support

Gaterotor Blade

Main Rotor

Damper Pin

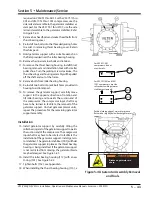

and Bushing

Clearance and Shims

Under 0.003”

0.003” – 0.004”

Over 0.004”

Remove shims

(103 in Figure

5-48, 106 in

Figure 5-42 &

5-44) to achieve

0.003” – 0.004”

Perfect!

Add shims (103

in Figure 5-48,

106 in Figure

5-42 & 5-44) to

achieve 0.003”

– 0.004”

Summary of Contents for Vilter VSH

Page 2: ......

Page 30: ...2 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 54: ...3 24 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 74: ...4 20 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 144: ...5 70 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 156: ...7 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 158: ...8 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 204: ...8 48 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 206: ...A 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 210: ...B 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 216: ...C 6 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 219: ......

Page 221: ......

Page 224: ......

Page 225: ......

Page 226: ......

Page 242: ...E 12 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 248: ...G 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 249: ......