Appendix C • Vibration Measurements - Single Screw Compressor

C − 4

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

Evaluation Zone limits

The values for the zone boundaries given below are

based on the maximum broad-band values of velocity

and displacement when measurements are taken from

two orthogonally oriented radial transducers. Therefore

when using these tables, the higher of each of the values

measured from the two transducers in each measure-

ment plane should be used. When the maximum mea-

sured values of velocity and displacement are compared

to the corresponding values in the table, the severity

zone which is most restrictive shall apply.

Operational limits

For long-term operation, it is common practice to es-

tablish operational vibration limits. These limits take the

form of ALARM and TRIP set points.

ALARM:

To provide a warning that a defined value of

vibration has been reached or a significant change has

occurred, at which remedial action may be necessary.

In general, if an ALARM situation occurs, operation can

continue for a period while investigations are carried out

to identify the reason for the change in vibration and de-

fine any remedial action.

TRIP:

To specify the magnitude of vibration beyond

which further operation of the machine may cause dam-

age. If the TRIP value is exceeded, immediate action

should be taken to reduce the vibration or the machine

should be shut down.

Different operational limits, reflecting differences in dy

-

namic loading and support stiffness, may be specified

for different measurement positions and directions.

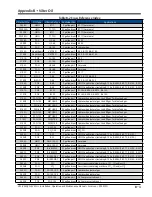

Table C-1. Vibration Zone Values

VIBRATION MEASUREMENTS – SINGLE SCREW COMPRESSOR*

Support

Class

ZONE

RMS Displacement

RMS Velocity

μmm

mils

mm/s

In/sec

A

0-30

0-1.15

0-2.3

0-.09

B

30-57

1.15-2.25

2.3-4.5

.09-.18

C

57-90

2.25-3.55

4.5-7.1

.18-.28

D

Above 90 Above 3.55 Above 7.1 Above .28

*RMS= 0.707 X peak (sine wave only)

Setting of ALARMS

The ALARM values may vary considerably, up or down,

for different machines. The values chosen will normally

be set relative to a baseline value determined from expe-

rience for the measurement position or direction for that

particular machine.

It is recommended that the ALARM value should be set

higher than the baseline by an amount equal to 25%

of the upper limit for zone B. If the baseline is low, the

ALARM may be below zone C.

Where there is no established baseline (for example

with a new machine) the initial ALARM setting should be

based either on experience with other similar machines

or relative to agreed acceptance values. After a period of

time, the steady-state baseline value will be established

and the ALARM setting should be adjusted accordingly.

It is recommended that the ALARM value should not

normally exceed 1.25 times the upper limit of zone B.

If the steady-state baseline changes (for example after a

machine overhaul), the ALARM setting should be revised

accordingly.

Setting of TRIPS

The TRIP values will generally relate to the mechanical in-

tegrity of the machine and be dependent on any specific

design features which have been introduced to enable

the machine to withstand abnormal dynamic forces. The

values used will, therefore, generally be the same for all

machines of similar design and would not normally be

related to the steady-state baseline value used for set-

ting ALARMS.

There may, however, be differences for machines of dif-

ferent designs and it is not possible to have clear guide-

lines for absolute TRIP values. In general, the TRIP value

will be within zone C or D, but it is recommended that

Summary of Contents for Vilter VSH

Page 2: ......

Page 30: ...2 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 54: ...3 24 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 74: ...4 20 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 144: ...5 70 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 156: ...7 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 158: ...8 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 204: ...8 48 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 206: ...A 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 210: ...B 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 216: ...C 6 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 219: ......

Page 221: ......

Page 224: ......

Page 225: ......

Page 226: ......

Page 242: ...E 12 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 248: ...G 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 249: ......