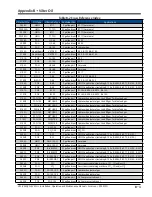

Appendix C • Vibration Measurements - Single Screw Compressor

C − 3

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

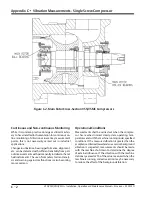

Figure C-3. Gaterotor Cross-Section VSS/VSR/VSMC Compressors

Evaluation

There are two evaluation criteria used to assess vibration

severity on various classes of machines. One criteria con-

siders the magnitude of observed broad-band vibration;

the second considers changes in magnitude, irrespec-

tive of whether they are increases or decreases.

Criterion 1: Vibration Magnitude

This criterion is concerned with defining limits for vibra

-

tion magnitude consistent with acceptable dynamic

loads on the bearings and acceptable vibration trans-

mission into the environment through the support

structure and foundation. The maximum vibration mag-

nitude observed at each bearing or pedestal is assessed

against the evaluation zones for the support class. The

evaluation zones have been established from interna-

tional experience.

The following evaluation zones are defined to permit a

qualitative assessment of the vibration of a given ma-

chine and provide guidelines on possible actions.

• Zone A: The vibration of newly commissioned ma-

chines would normally fall within this zone.

• Zone B: Machines with vibration within this zone

are normally considered acceptable for unrestricted

long-term operation.

• Zone C: machines with vibration within this zone are

normally considered unsatisfactory for long term

continuous operation. Generally, the machine may

be operated for a limited period in this condition un-

til a suitable opportunity arises for remedial action.

• Zone D: Vibration values within this zone are nor-

mally considered to be of sufficient severity to cause

damage to the machine.

Numerical values assigned to the zone boundaries are

not intended to serve as acceptance specifications,

which shall be subject to agreement between Vilter

TM

manufacturing and the customer. However, these val-

ues provide guidelines for ensuring that gross deficien

-

cies or unrealistic requirements are avoided. In certain

cases, there may be specific features associated with a

particular machine which would require different zone

boundary values (higher or lower) to be used

Summary of Contents for Vilter VSH

Page 2: ......

Page 30: ...2 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 54: ...3 24 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 74: ...4 20 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 144: ...5 70 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 156: ...7 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 158: ...8 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 204: ...8 48 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 206: ...A 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 210: ...B 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 216: ...C 6 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 219: ......

Page 221: ......

Page 224: ......

Page 225: ......

Page 226: ......

Page 242: ...E 12 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 248: ...G 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 249: ......