5 – 35

Section 5 • Maintenance/Service

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

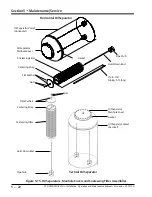

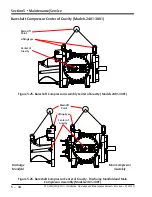

Main Rotor Bearing Axial Clearance Inspection

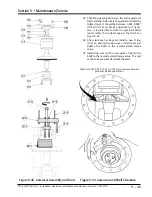

To inspect bearing axial clearance, proceed with the fol-

lowing steps:

1. Remove center member, see appropriate Drive

Coupling Replacement procedure.

2. Install dial indicator to the compressor frame and

zero indicator, see Figure 5-27.

3.

Place lever arm and fulcrum behind compressor

coupling half and push the coupling towards the

motor. Record measurement.

4. Re-zero indicator, now position the fulcrum on the

motor and use the lever arm to push the input shaft

towards the compressor. Record measurement

5. Add both measurements. If measurement is out

of allowable tolerance shown in Table 5-10, the

bearing may need to be replaced. Contact Vilter

TM

Technical Support.

Top View

Small wooden block or fulcrum.

Direction of

shaft movement.

Shaft being pushed by use of lever.

Applied Force

Rigidly attach dial indicator.

Position on axis of compressor.

Top View

Wooden block

or fulcrum

Direction of

shaft movement.

Rigidly attach dial indicator.

Position on axis of compressor.

Applied Force

Shaft being pushed by use of lever.

Figure 5-27. Bearing Axial Clearance

Inspection

Compressor Inspection

Compressor Shaft Bearing Clearance

Inspections

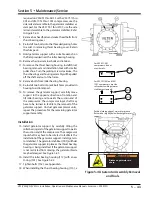

If clearance measurements are out of tolerance, contact

Vilter Technical Support for further assistance.

CAUTION

When taking the measurements, do not exceed

300 to 500 lbs of force at point of contact or

damage may result to the bearings.

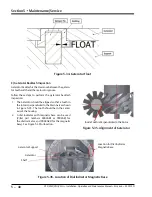

Determine Maximum Applied Force

To determine maximum applied force, take maximum

applied force at hub/shaft multiplied by length of A

and divide by length B. This is the maximum force that

should be applied on the lever.

(Applied Force x A)/B = Applied Force (Maximum)

So, using a 36” (or 1 m) lever with pivot space of 6” (or

15 cm) would make the maximum applied force to be 60

lbf (or 235 N). Calculation is as follows:

(300 lbf x 6”)/30” = 60 lbf (Max.

Applied Force

)

(1335 N x 15 cm)/85 cm = 235 N (Max.

Applied Force

)

B

A

Lever

Wooden Block

or Fulcrum

Applied

Force

Force at

Hub/Shaft

Pivot Point

As a quick reference, Table 5-10 shows maximum ap-

plied forces for 36” lever with 6” pivot for all compres-

sor models.

Summary of Contents for Vilter VSH

Page 2: ......

Page 30: ...2 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 54: ...3 24 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 74: ...4 20 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 144: ...5 70 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 156: ...7 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 158: ...8 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 204: ...8 48 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 206: ...A 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 210: ...B 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 216: ...C 6 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 219: ......

Page 221: ......

Page 224: ......

Page 225: ......

Page 226: ......

Page 242: ...E 12 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 248: ...G 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Page 249: ......