H1_Construct multi-dispense working point

Step 3: Construct dispense point and array expand dispense working point

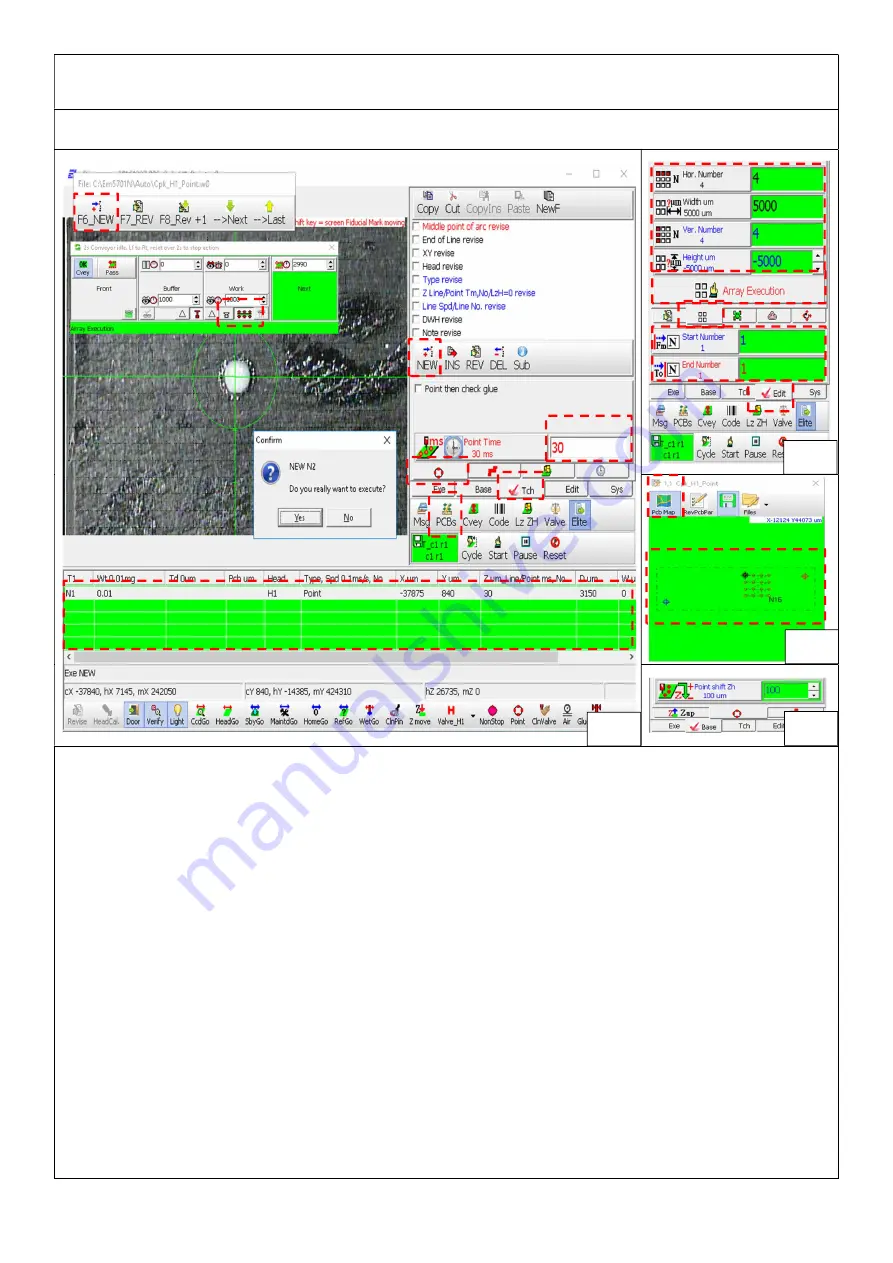

1.

Conveyor belt empty clamp, Pic. 1

2.

Working point column, Pic. 1

3.

Select teach, Pic. 1

4.

Select dispense, Pic. 1

5.

Input single dispense, stop seconds(initial 30ms start testing glue), Pic. 1

6.

CCD move to dispense platform’s left up position, press F6 on keyboard or click new interface. Construct glue working

point, Pic. 1

7.

Select edit,. Pic. 2

8.

Select array, Pic. 2

9.

Input amount and distance, according to first dimension as pvalue(can use this parameter), Pic. 2

10.

Input starting point N1 working point, N1 end working point, Pic. 2

11.

Expand array function button, Pic. 2

12.

Select connecting PCBs, Pic. 3

13.

Switch working diagram, Pic. 3

14.

Blue dot is base B0, Red dot is B1, Black dot is current CCD position, Red dot is dispense workign point, Pic. 3

15.

Select base, set dispense height(height will impact dispense residue amount), Pic. 4

2

3

4

5

5

6

7

8

9

11

10

Pic.2

Pic.3

Pic.4

Pic.1

1

12

13

14

Summary of Contents for 5701N

Page 3: ...Pic 1 3 ...

Page 6: ...Pic 1 3 ...

Page 11: ...Pic 1 ...

Page 13: ...Pic 1 3 ...

Page 16: ...12 Red disk will show click left key of mouse to save system file ...

Page 18: ...Pic 1 ...

Page 20: ......

Page 24: ...3 Check if valve is clogged 4 Check if needle is clogged ...

Page 43: ...Plastic Needle head specifications When to use Choose needle size according to glue amount ...