1-54

12H-M12M0-0309-0

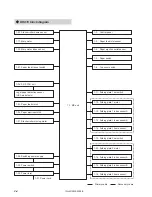

4-10. When Folding Misalignment Along Vertical Length of Paper is Large

Cause

Solution

Thrust play of the screw shaft unit

is large.

The full nut has worn out, and the

thrust play of the area connected

the screw shaft is large.

Adjust so that the thrust play becomes 0.1 to less than 0.15 mm (0.004" to

less than 0.006").

“2-6-2. Checking and adjusting the thrust play of the screw shaft

unit”

Replace the full nut.

“2-6-3. Replacing the full nut”

4-11. When Folding Misalignment Along Sides of Paper is Large

Cause

Solution

Paper is conveyed skewed.

Paper lead edge and folding

stopper are not parallel.

Perform “4-1. When Paper is Conveyed Skewed”.

Adjust the parallelity of the folding stopper.

“2-6-10. Adjusting the parallelity of the folding stoppers”

4-12. Paper Jams at Folding Unit or Flattening of Folded Line Occurs During

Single Folding and When Thick Paper is Used, or Folding Wrinkle Line is

Formed at Folded Line with Thin Paper

Cause

Solution

The clearance between the folding

roller and switching shaft is too

large.

Adjust the clearance.

“2-6-11. Adjusting the home position of the switching shaft

(stopping position) in single folding”

4-13. Paper Jams at Folding Unit or Flattening of Folded Line Occurs During

Folding Modes Other Than Single Folding and When Thick Paper is Used

Cause

Solution

As the conveyance route is too

narrow, the thick paper does not

enter the folding rollers easily.

Increase the processing speed.

“2-6-12. (1) Setting the thick paper mode”

Change the stopping position of the switching shaft, and widen the

conveyance route.

“2-6-12. (2) Removing the stopper (collar) of the switching shaft”

4-14. When Motor Lock of Folding Plate 2 Occurs

Cause

Solution

The frictional coefficient of the

cushion (urethane sheet) surface

of the switching shaft is high,

exceeding the allowed current

during motor drive.

Decrease the frictional coefficient.

“2-6-13. Switching shaft cushion (urethane sheet)”

See

See

See

See

See

See

See

See

See

See

See

See

See

See