1-27

12H-M12M0-0309-0

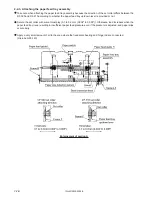

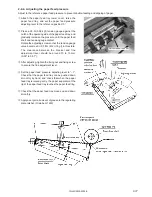

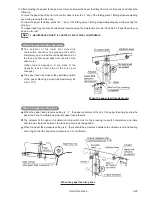

2-5-3. Paper ejection roller lever unit

The basic configuration of this unit is more or less the same as the DF-520N.

If the paper ejection roller lever unit has been removed during the replacement of the drive motor, attach it using the

following procedure.

q

Apply a very small amount of oil to the area where the

drive shaft of the paper ejection roller lever unit and

bearing are connected. (Orelube G90-140)

w

Check that there is appropriate backlash (0.1 to 0.2

mm (0.004" to 0.008")) at the area where the drive

gear of the paper ejection roller lever unit and pinion

are engaged, and that they rotate smoothly.

e

Apply grease to the engaged gear teeth.

(Orelube G1650)

r

Secure the set screw of the drive gear, and apply a

very small amount of thread locking to the set screw.

(Loctite 242: Medium strength)

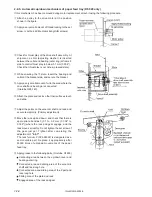

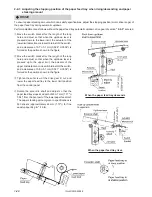

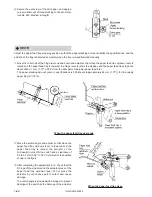

2-5-4. Adjusting and checking the stacker roller home sensor

The stopping position of the stacker roller moves automatically in six steps according to the folded paper length.

The moving distance is controlled by the moving duration from the home sensor.

q

When the switch lever is at the home position, secure

the sensor bracket with a clearance of 2.0 to 2.5 mm

(0.08" to 0.10") between the switch lever shield and

home sensor.

w

After adjusting, check that the home sensor turns ON

and OFF properly in the maintenance mode.

“3. MAINTENANCE MODE” in CHAPTER 2

ELECTRICAL COMPONENTS

See

See