1-52

12H-M12M0-0309-0

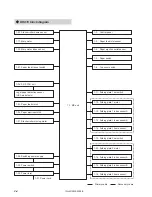

4. TROUBLESHOOTING GUIDE (MECHANICAL CAUSES)

4-1. When Paper is Conveyed Skewed

Cause

Solution

The left and right nip amount

differs between the folding rollers.

The thrust play of the folding roller

drive gear is large.

The press pressure of the folding

roller is not balanced between the

left and right sides.

The folding roller is deformed.

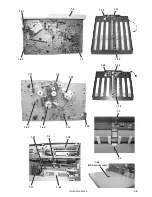

Check the attached state of the reference stopper, and make the roller nip

the same.

“2-1-2. (3) Attaching the reference stoppers”

“2-1-2. (4) Attaching the drive gear (helical gear) of folding roller”

Adjust so that there is no thrust play.

“2-1-2. (4) Attaching the drive gear (helical gear) of folding roller”

Adjust the press pressure.

“2-1-2. (6) Attaching the press spring T”

Replace the folding roller.

“2-1-2. Replacing folding rollers”

Cause

Solution

The press pressure of the folding

roller is strong.

The folding roller is deformed.

Adjust the press pressure.

Especially set the press pressure of folding roller 1 weak. (About 45 to 46 mm

(1.77" to 1.81"))

“2-1-2. (6) Attaching the press spring T”

Replace the folding roller.

“2-1-2. Replacing folding rollers”

Cause

Solution

The plate spring for grounding

conduction has worn out.

Apply conductive grease or replace the plate spring.

“2-1-2. (7) Attaching the plate spring (grounding conduction)”

Cause

Solution

The thrust play of the paper

ejection drive shaft and paper

ejection clutch is not appropriate.

Adjust so that the thrust play is less than 0.1 mm (0.004").

“2-1-4. Paper ejection drive shaft”

See

See

See

See

See

See

See

See

4-2. When Paper Wrinkles

See

See

See

See

4-3. When Abnormal Sounds (Metal Sliding Sounds) are Produced During

Rotation of Folding Rollers

See

See

4-4. When Stacker Belt Rotates Heavily

See

See