1-24

12H-M12M0-0309-0

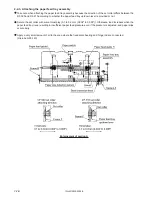

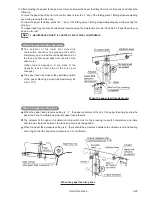

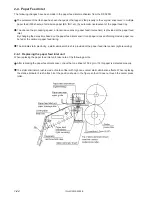

2-4. Paper Feed Inlet

The following changes have been made in the paper feed inlet mechanism from the DF-520N.

The curvature of the rib shape has been changed so that paper is fed properly to the very last sheet even in multiple

paper feed (500 sheets) of small size paper (B6, INV, etc.) by automatic rise/descent of the paper feed tray.

To enhance the processing speed, a transmissive sensor (paper feed inlet sensor) is provided at the paper feed

inlet.

By changing the delay time based on the paper feed inlet sensor for all paper sizes and folding modes, paper can

be fed at the optimum paper feed timing.

To eliminate static electricity, a static eliminator brush is provided at the paper feed inlet sensor (light-receiving).

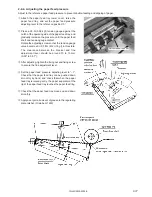

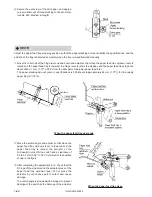

2-4-1. Replacing the paper feed inlet unit

When replacing the paper feed inlet unit, take note of the following points.

After replacing the paper feed inlet sensor, check that one sheet of 52.4 g/m

2

(14 lb) paper is detected properly.

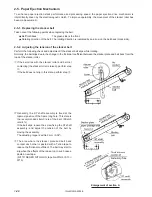

The static eliminator brush is made of carbon fiber with high non-contact static elimination effects. When replacing

the static eliminator brush, attach it at the position shown in the figure so that it does not touch the center press

roller.