1-12

12H-M12M0-0309-0

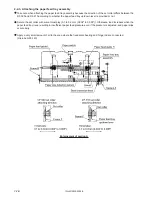

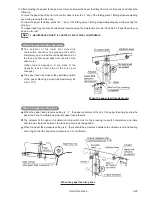

2-1-4. Paper ejection drive shaft

The stacker belt is driven at high speed intermittently using the electromagnetic clutch to enhance stacking

performance and processing speed.

Replace the paper ejection clutch using the following

procedure.

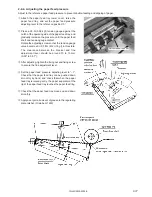

q

Check the accessories provided with the paper

ejection clutch unit.

Shim (adjusting washer, t = 0.1): 3

Collar: 1

w

Check for thrust play of the paper ejection drive shaft

at frame F side. At shipment, a shim (adjusting

washer) is inserted between the paper ejection drive

shaft and bearing to control thrust play to below 0.1

mm (0.004").

Check that thrust play is not minus (pressed state).

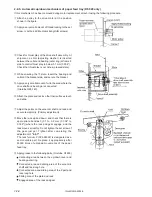

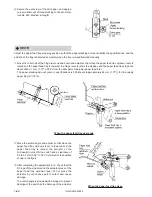

e

While ensuring the

w

state, attach and secure the

clutch rotor at frame B side.

r

Attach the collar, shim, armature (STS pulley)

provided with the paper ejection clutch unit as a set to

the drive shaft.

As the paper ejection clutch unit is adjusted

to an air gap (0.15 mm (0.006")) at shipment,

always attach the above parts to the

machine as a set.

Do not apply oil to the contacting area of the

clutch rotor and armature.

Note

Note

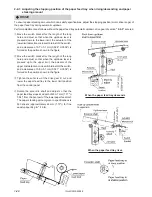

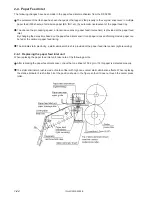

t

Using the shim provided, adjust so that thrust play of

the collar and E ring outside the armature becomes

less than 0.1 mm (0.004").

y

Check that the armature rotates smoothly.

Also check that paper ejection drive shaft does not

rotate when the armature rotates.

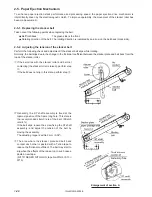

u

Apply a very small amount of oil to the area where the

drive shaft and bearing are connected.

(Orelube G90-140)