DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

27

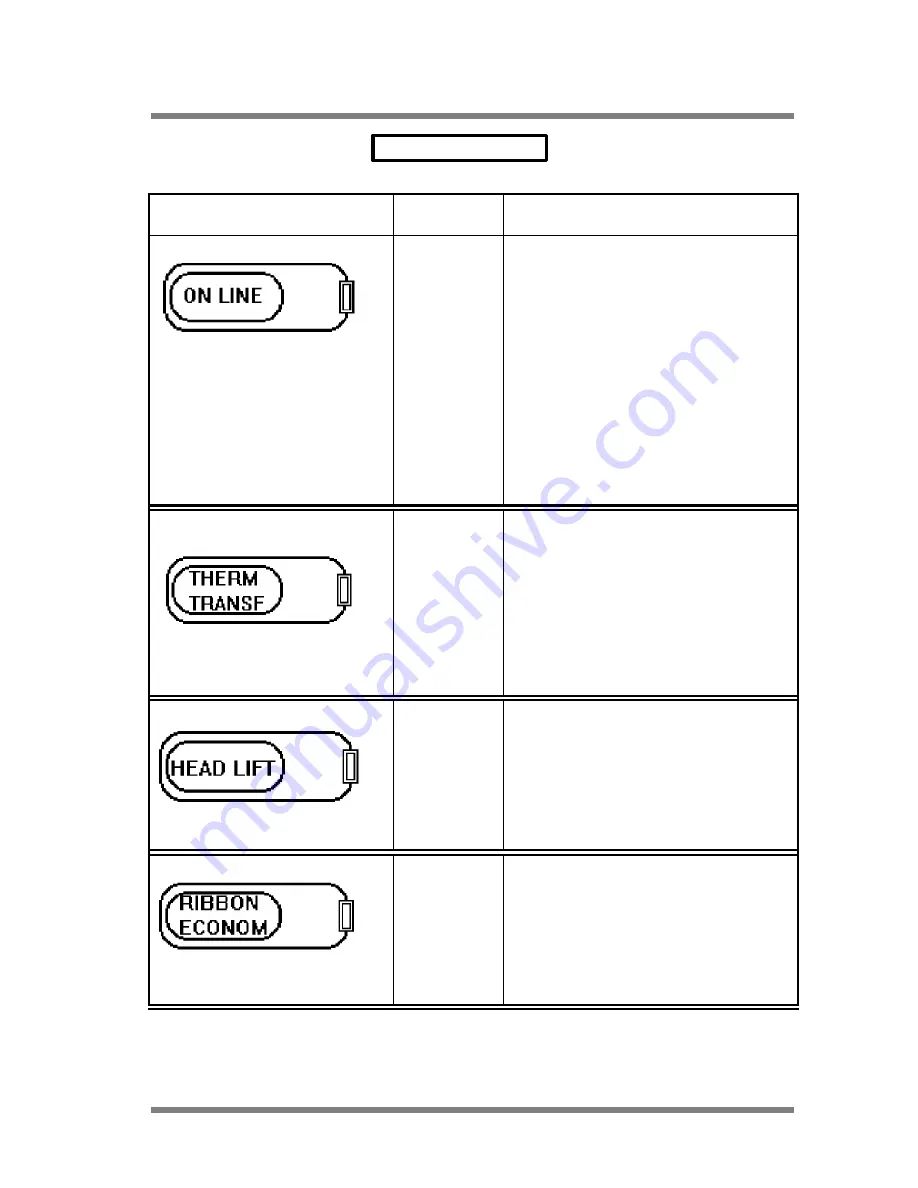

LIGHT LEDS TABLE

LIGHT LED

STATUS

MEANING

ON

OFF

FLASH

The printer in ON LINE status and is ready to

execute the commands coming from serial line.

The printer can be both in printing status or in

OFF LINE. It is not possible to execute line

commands that will be stored on the buffer with

exception of those executable in real time.

The printer can be both in printing status or in

OFF LINE. It is not possible to execute line

commands that will be stored on the buffer with

the exception of those executable in real time.

ON

OFF

The printer is ready to print in thermal/transfer

mode.

The printer is ready to print in direct thermal

ON

OFF

The printhead is lifted by its motor and the

printer is ready to execute special functions.

The printhead is in contact with the paper

(normal functioning mode).

ON

OFF

The economizer device is abled.

The economizer device is disabled.