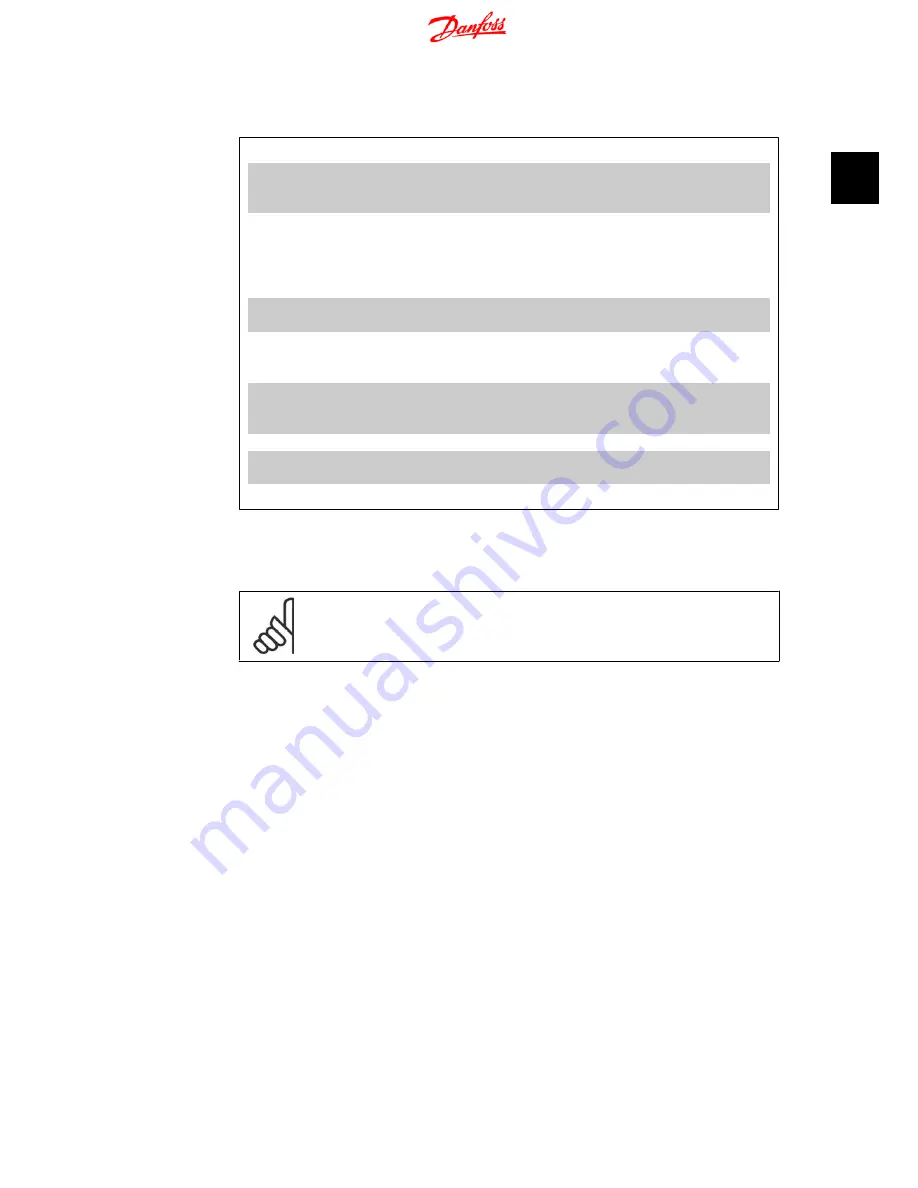

2.7.3. MCO 350 Terminal X59

I/O Number Designation

Description

1

O1 - READY

Ready, i.e. for the number of marker signals that were

specified in Parameter 3325, the slave drive has run

within the tolerance (Accuracy).

2

O2 - FAULT

Fault, i.e. for the number of marker signals that were

specified in Parameter 3324, the slave drive has run out-

side the tolerance (Accuracy). OR when the number of

marker signals have been missing when marker monitor

is activated in parameter 1923.

3

O3 - ACCURACY

The drive runs within the tolerance specified in Param-

eter 3313.

4

O4 - Brake control

This output can be used to control a mechanical brake.

“0” means that the brake must be closed (braking) “1”

means that the brake must be open (not braking)

5

O5 - Saving

This output stays high while saving is in progress. The

saving is initiated by Parameter 1900, Input 4 or fieldbus

bit 4.

6

O6 - Drive running

Signal “1” when the drive is running.

7

O7 - Home reached If the data value “1” was chosen in Parameter 3300, this

output shows “1” when homing is completed.

8

O8 - Ready, no error The synchronising controller is ready for operation.

2.8. Description of Fieldbus Interface

NB!

This section is only relevant if the VLT is equipped with a Field bus interface (option)

as well as the synchronising controller.

The synchronising controller can be controlled via the digital/analogue inputs or via field bus. The

control source can be selected individually for test-run and synchronising in the parameters 1919

(test-run) and 1920 (synchronising). There can only be one control source at a time meaning that

the digital/analogue inputs are inactive when Field bus is selected as control source and visa versa.

The only exception is input 27, which is always stop/enable also when Field bus is selected as

control source. In synchronising mode three signals are only available as digital inputs even when

Field bus is selected as control source that is the marker signals for marker synchronisation and

the Home switch. This is because these signals are too time-critical for Field bus control. Status

signals are always available on the digital/analogue outputs but they are only available via Field

bus when Field bus is selected as control source.

2.8.1. Data Layout

Control and status signals are transferred via the so-called process data channel (PCD) of the

various fieldbus interfaces. The telegram structure and the available number of data words de-

pends on the Fieldbus used, please refer to the manual of the Fieldbus option in use for further

details. The below example is based on the layout of a PROFIBUS telegram, the so-called PPO:

Example using PROFIBUS PPO type 5:

Syncronising Controller MCO 350 Operating

Instructions

2. Introduction

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

23

2