recommended, especially where cables run in

parallel, over long distances, or if drives with a

bigger power size is installed. More information

can be found in the norm IEC 61000-5-2:1997.

4.

When crossing of cables is unavoidable, the

Ethernet cable must cross motor and brake

resistor cables at an angle of 90

°

.

5.

Always observe relevant national and local

regulations, for example regarding protective

earth connection.

NOTE

In a line topology all frequency converters must be

powered, either by mains or by their 24 V DC option cards,

for the built-in POWERLINK slave controller to work.

2.1.6 EMC Precautions

To achieve interference-free operation of the Ethernet,

observe the following EMC precautions. Additional EMC

information is available in the

VLT

®

AutomationDrive Design

Guide.

NOTE

The correct handling of the shield of the motor cable is

vital for the overall performance of the system. If the rules

are not followed it can lead to loss of the control and

malfunction of the system.

NOTE

Always observe relevant national and local regulations, for

example regarding protective earth connection.

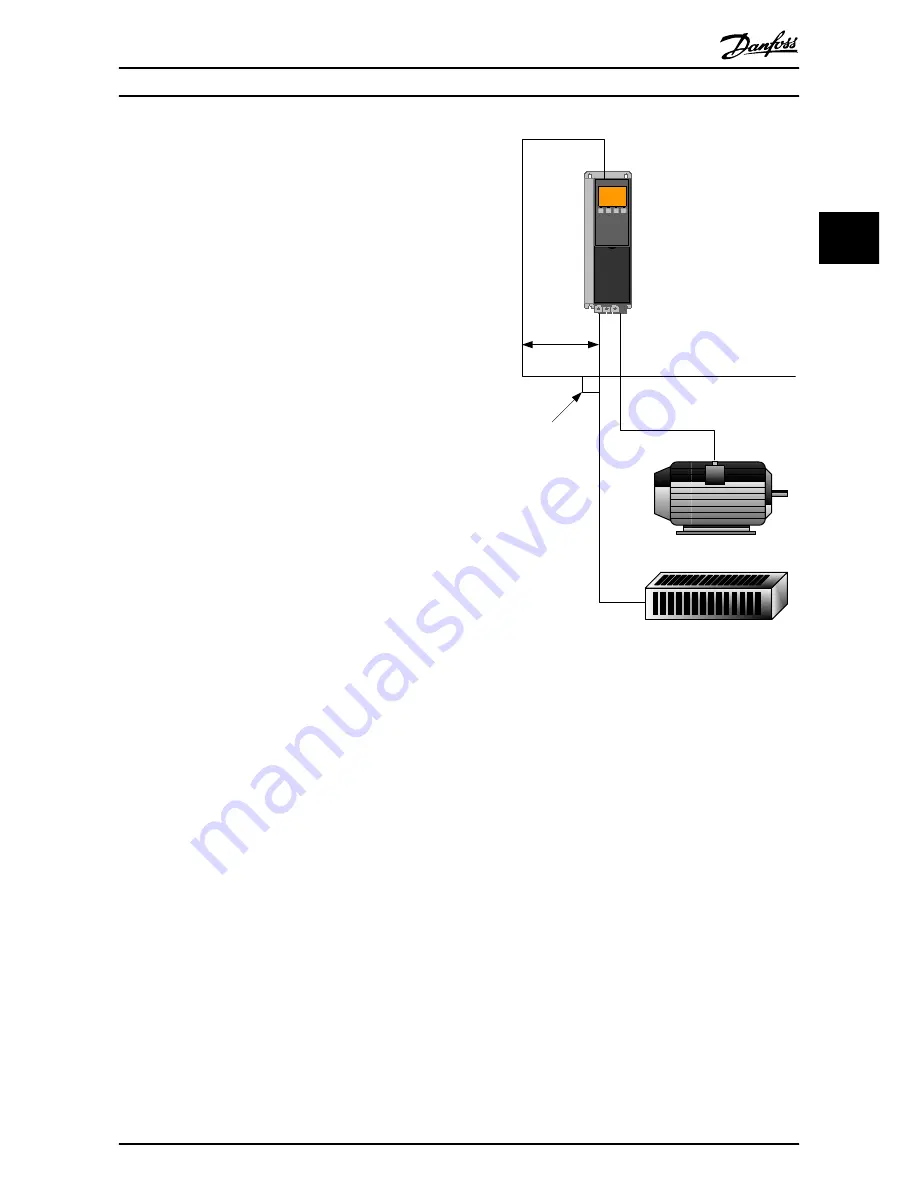

The Ethernet communication cable must be kept away

from motor and brake resistor cables to avoid coupling of

high frequency noise between the cables. When crossing is

unavoidable, the Ethernet cable must cross motor and

brake resistor cables at an angle of 90

°

.

min. 200 mm

90 ° crossing

Ethernet Cable

130BA908.11

Illustration 2.5 Correct Crossing of Ethernet Cable

How to Install

MCA 123 POWERLINK Operating Instructions

MG92C102 - VLT

®

is a registered Danfoss trademark

9

2

2