Si39-504

Specifications

Specifications

31

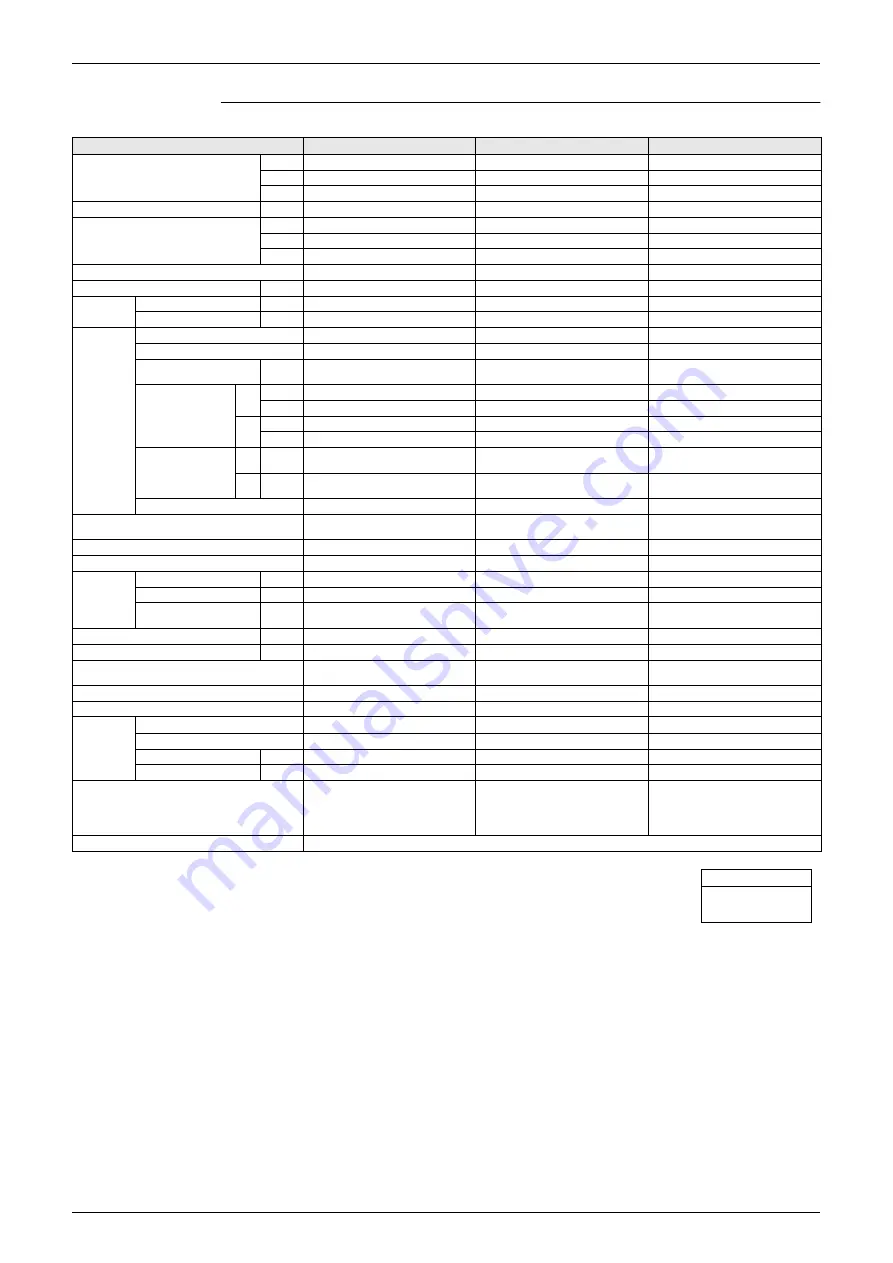

Ceiling Mounted Built-in Type

Notes:

1 Indoor temp. : 27°CDB, 19.5°CWB / outdoor temp. : 35°CDB / Equivalent piping length : 7.5m, level

difference : 0m.

2 Indoor temp. : 27°CDB, 19.0°CWB / outdoor temp. : 35°CDB / Equivalent piping length : 7.5m, level

difference : 0m.

3 Indoor temp. : 20°CDB / outdoor temp. : 7°CDB, 6°CWB / Equivalent piping length : 7.5m, level difference :

0m. (Heat pump only)

4 External static pressure is changeable to change over the connectors inside electrical box, this pressure

means

“High static pressure-Standard -Low static pressure”.

5 Capacities are net, including a deduction for cooling (an additional for heating) for indoor fan motor heat.

6 Anechoic chamber conversion value, measured at a point 1.5m downward from the unit center. These

values are normally somewhat higher during actual operation as a result of ambient conditions.

Model

FXSQ40MVE

FXSQ50MVE

FXSQ63MVE

1 Cooling Capacity (19.5°CWB)

kcal/h

4,000

5,000

6,300

Btu/h

16,000

19,800

24,900

kW

4.7

5.8

7.3

2 Cooling Capacity (19.0°CWB)

kW

4.5

5.6

7.1

3 Heating Capacity

kcal/h

4,300

5,400

6,900

Btu/h

17,100

21,500

27,300

kW

5.0

6.3

8.0

Casing

Galvanized Steel Plate

Galvanized Steel Plate

Galvanized Steel Plate

Dimensions: (H×W×D)

mm

300×700×800

300×700×800

300×1,000×800

Coil (Cross

Fin Coil)

Rows×Stages×Fin Pitch

mm

3×14×1.75

3×14×1.75

3×14×1.75

Face Area

m²

0.132

0.132

0.221

Fan

Model

D18H2A

D18H2A

2D18H2A

Type

Sirocco Fan

Sirocco Fan

Sirocco Fan

Motor Output × Number of

Units

W

65×1

85×1

125×1

Air Flow Rate (H/L)

50

Hz

m³/min

11.5/9

15/11

21/15.5

cfm

406/318

530/388

741/547

60

Hz

m³/min

11.5/9

15/11

21/14

cfm

406/318

530/388

741/494

4

External Static

Pressure

50

Hz

Pa

88-49-20

88-59-29

88-49-20

60

Hz

Pa

88-29-10

88-41-10

122-66-10

Drive

Direct Drive

Direct Drive

Direct Drive

Temperature Control

Microprocessor Thermostat for

Cooling and Heating

Microprocessor Thermostat for

Cooling and Heating

Microprocessor Thermostat for

Cooling and Heating

Sound Absorbing Thermal Insulation Material

Glass Fiber

Glass Fiber

Glass Fiber

Air Filter

Resin Net (with Mold Resistant)

Resin Net (with Mold Resistant)

Resin Net (with Mold Resistant)

Piping

Connections

Liquid Pipes

mm

φ

6.4 (Flare Connection)

φ

6.4 (Flare Connection)

φ

9.5 (Flare Connection)

Gas Pipes

mm

φ

12.7 (Flare Connection)

φ

12.7 (Flare Connection)

φ

15.9 (Flare Connection)

Drain Pipe

mm

VP25

(External Dia. 32 Internal Dia. 25)

VP25

(External Dia. 32 Internal Dia. 25)

VP25

(External Dia. 32 Internal Dia. 25)

Machine Weight (Mass)

kg

30

31

41

6 Sound Level (H/L) (220V)

dBA

38/32

41/36

42/35

Safety Devices

Fuse.

Thermal Protector for Fan Motor.

Fuse.

Thermal Protector for Fan Motor.

Fuse.

Thermal Protector for Fan Motor.

Refrigerant Control

Electronic Expansion Valve

Electronic Expansion Valve

Electronic Expansion Valve

Connectable Outdoor Unit

R-410A M(A) Series

R-410A M(A) Series

R-410A M(A) Series

Decoration

Panel

(Option)

Model

BYBS45DJW1

BYBS45DJW1

BYBS71DJW1

Panel Color

White (10Y9/0.5)

White (10Y9/0.5)

White (10Y9/0.5)

Dimensions: (H×W×D)

mm

55×800×500

55×800×500

55×1,100×500

Weight

kg

3.5

3.5

4.5

Standard Accessories

Operation Manual. Installation

Manual. Paper Pattern for Installation.

Drain Hose. Clamp Metal. Insulation

for Fitting. Sealing Pads. Clamps.

Screws. Washers.

Operation Manual. Installation

Manual. Paper Pattern for Installation.

Drain Hose. Clamp Metal. Insulation

for Fitting. Sealing Pads. Clamps.

Screws. Washers.

Operation Manual. Installation

Manual. Paper Pattern for Installation.

Drain Hose. Clamp Metal. Insulation

for Fitting. Sealing Pads. Clamps.

Screws. Washers.

Drawing No.

C : 3D039431

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Summary of Contents for VRV II RXYQ5MATL

Page 53: ...Specifications Si39 504 42 Specifications...

Page 115: ...Outline of Control Indoor Unit Si39 504 104 Function...

Page 161: ...Field Setting Si39 504 150 Test Operation...

Page 172: ...Si39 504 Troubleshooting by Remote Controller Troubleshooting 161...

Page 266: ...Si39 504 Piping Diagrams Appendix 255 RXYQ8MA 10MA 12MAYL E TL E 3D048033A...

Page 267: ...Piping Diagrams Si39 504 256 Appendix RXYQ14MA 16MAYL E TL E 3D048034A...

Page 271: ...Wiring Diagrams for Reference Si39 504 260 Appendix RXYQ8MA 10MA 12MAYL E 3D047088C...

Page 272: ...Si39 504 Wiring Diagrams for Reference Appendix 261 RXYQ14MA 16MAYL E 3D047089C...

Page 273: ...Wiring Diagrams for Reference Si39 504 262 Appendix 2 1 2 RXYQ MATL E RXYQ5MATL E 3D049059A...

Page 274: ...Si39 504 Wiring Diagrams for Reference Appendix 263 RXYQ8MA 10MA 12MATL E 3D049060A...

Page 275: ...Wiring Diagrams for Reference Si39 504 264 Appendix RXYQ14MA 16MATL E 3D049061A...

Page 283: ...Wiring Diagrams for Reference Si39 504 272 Appendix FXCQ40M 50M 80M 125MVE 3D039557A...

Page 285: ...Wiring Diagrams for Reference Si39 504 274 Appendix FXKQ25M 32M 40M 63MVE 3D039564B...

Page 289: ...Wiring Diagrams for Reference Si39 504 278 Appendix FXMQ40M 50M 63M 80M 100M 125MVE 3D039620B...

Page 290: ...Si39 504 Wiring Diagrams for Reference Appendix 279 FXMQ200M 250MVE 3D039621B...

Page 291: ...Wiring Diagrams for Reference Si39 504 280 Appendix FXHQ32M 63M 100MVE 3D039801D...

Page 292: ...Si39 504 Wiring Diagrams for Reference Appendix 281 FXAQ20M 25M 32MVE 40M 50M 63MVE 3D034206C...

Page 309: ...Selection of Pipe Size Joints and Header Si39 504 298 Appendix Note 1...

Page 315: ...Method of Replacing The Inverter s Power Transistors and Diode Modules Si39 504 304 Appendix...