5.5.6. Bleeding the fuel system

After the cleaning of the fuel filter or after the

engine stop by the lack of fuel, the bleeding

of the fuel system must be executed by all

means.

Bleed the system by manually operating the

priming pump with fuel filter outlet joint bolt

and injection pump bleeder screw loosened.

•

Press the feed pump cap repetitively until

the fuel without bubbles comes out from

the bleeding valves.

•

After the whole air is pulled out, close the

valve of the filter.

•

Confirm the resistance of fuel delivery by the repetition pressing of the feed pump cap,

Pressure and turn the feed pump cap simultaneously to close it.

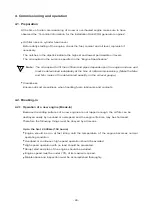

5.5.7. Injection pump

•

Check the fuel injection pump housing for cracks or breaks, and replace if damaged.

•

Check and see if the lead seal for idling control and speed control levers have not been

removed.

•

No alterations must be made to the injection pump. If the lead seal is damaged the warranty

on the engine will become null and void.

•

We strongly recommended that any faults developing in the injection pump should be taken

care of by authorized specialist personnel.

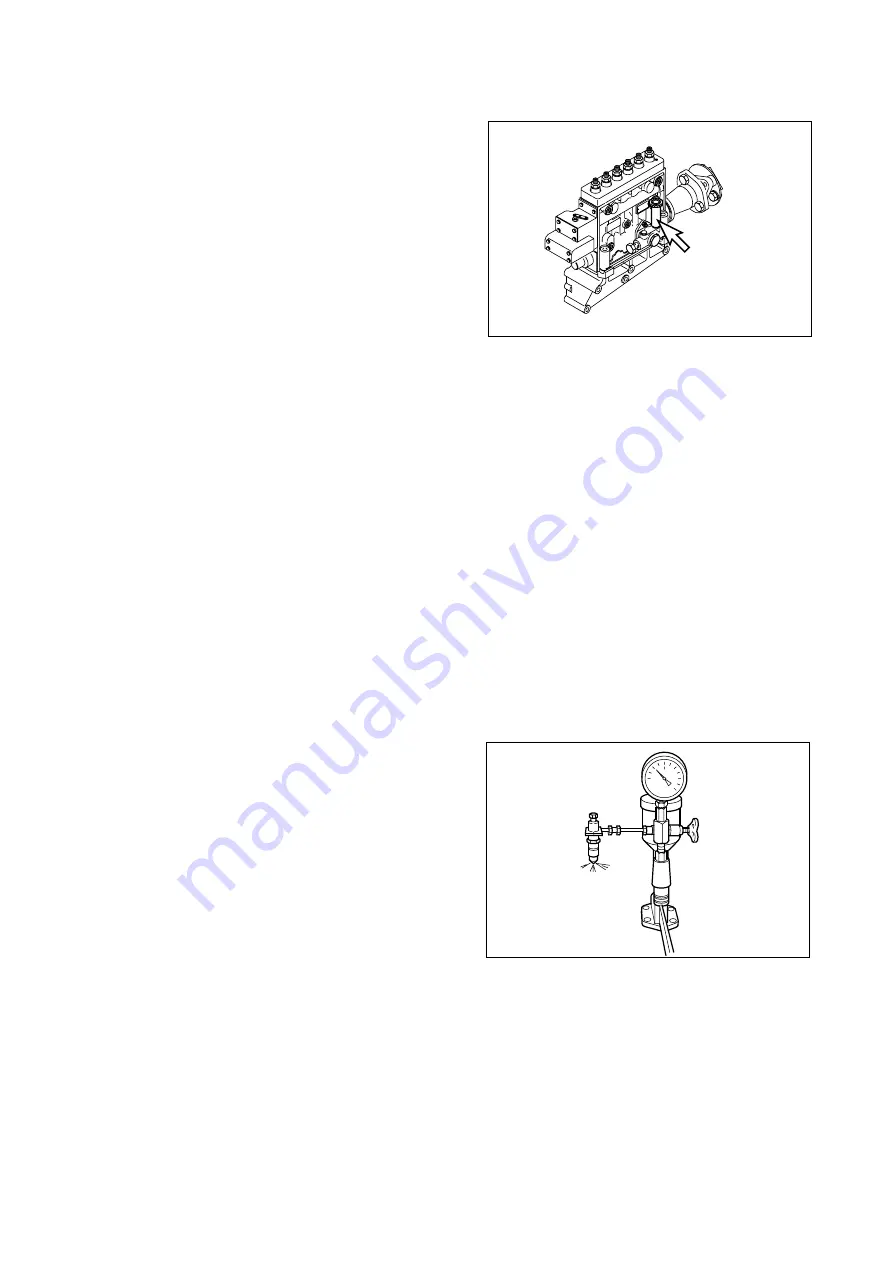

5.6. Injection Nozzle Maintenance (by authorized specialist personnel)

The injectors are designed to spray the fuel

delivered by the injection pump directly into

the spherical combustion chamber in the

piston crown.

The injector consists of the nozzle and the

nozzle holder.

A copper seal fitted to the injector ensures

gas-tight seating and good heat dissipation.

The opening pressure of the nozzle is

adjusted by means of shims at the

compression spring.

- 39 -

EA9O4005

Priming pump

EA0M3003