3.2.11. Connecting rod

1) Distorsion

Check the connecting rod for distortion.

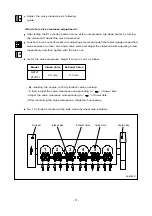

As shown in the figure below, install the

connecting rod to the connecting rod

tester, and check for distortion using a

feeler gauge. If the connecting rod is

found distorted, never re-use it but

replace with a new one.

2) Holes alignment (parallelism)

Measure the alignment of the connecting

rod piston pin bushing holes with con-

necting rod big end holes. At this time

also, use both connecting rod tester and

feeler gauge.

3) Wear

•

Assemble the connecting rod to the

crankshaft and measure connecting

rod big end side clearance using a feel-

er gauge.

•

Assemble the connecting rod to the

piston and measure connecting rod

small end side clearance.

•

If the measured values are beyond the

limit, replace the connecting rod.

- 57 -

EA0M4034

Standard

Limit

0.05 mm

0.1 mm or less

Limit

0.5 mm