10.7

Configuration of the resolution, speed and acceleration of the axes

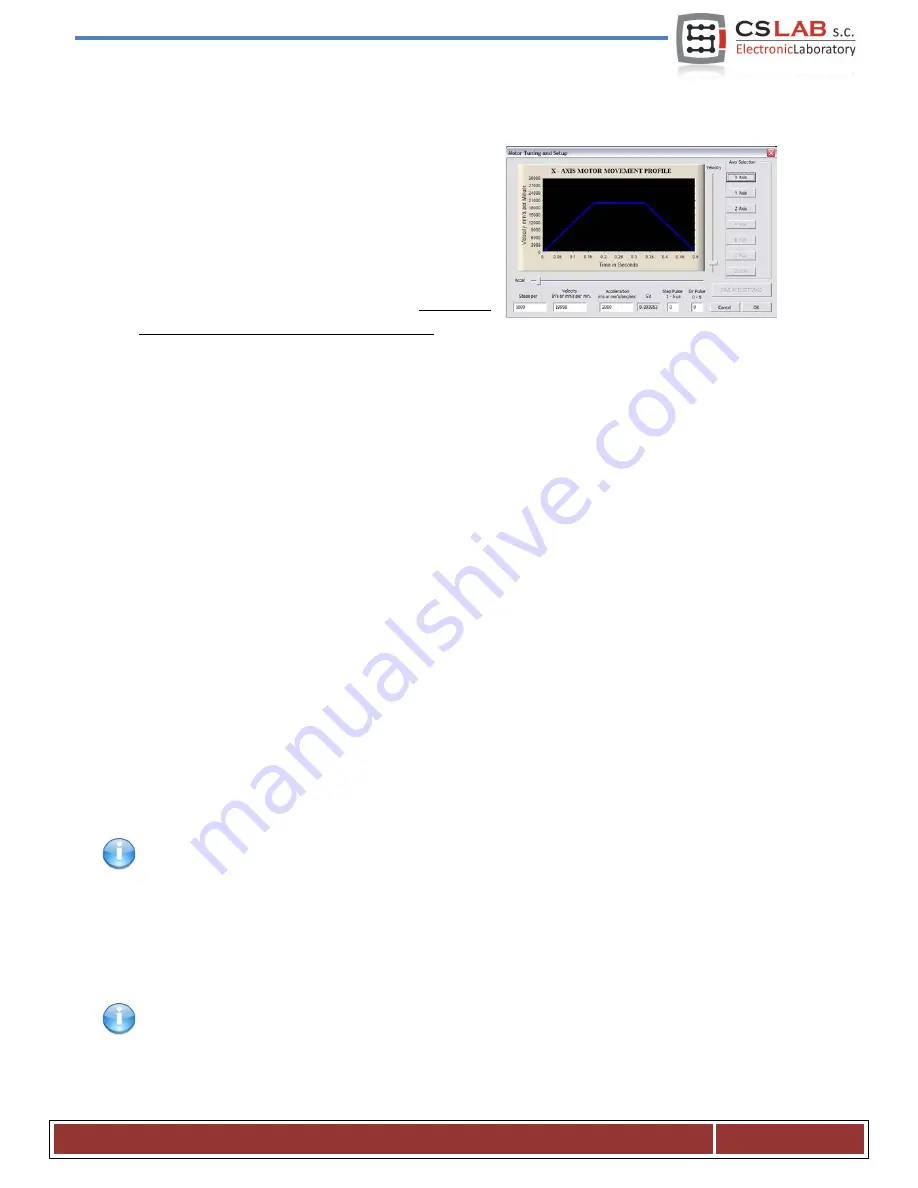

Before starting the work, it is necessary to set correctly

the resolution (called scaling) of the axis and to set their

max. speed and accelerations -in the Mach3 program -

„Config/Motor Tuning” menu. In the window, first select

the axis you want to configure, next enter the parameters

and click on „SAVE AXIS SETTINGS”. Now you can select

and set the next axis. If we forget to click on „SAVE AXIS

SETTINGS” all entered changes will not be saved.

For the correct axis scaling you must know the number of steps per unit (millimeter, inch or degree).

To understand how to calculate it, look at the example below:

•

The servomotor powers the line axis with 10000 rpm encoder.

•

The servo drive is configured without a multiplier and electronic gear, so 10000 STEP pulses

cause a 1 rev of the motor.

•

To transfer the drive there was used a ball screw - pitch

10mm

.

•

No ratio between the motor and the screw.

There are 10000 pulses per motor revolution and feed rate is 10mm per revolution. Dividing this value

10000 pulses/10mm we get 1000 pulse = 1mm movement, which we enter into the “Steps Per” box in the

configuration window.

In the „Velocity”, we set the axis speed. If we are using the millimeters as an unit then the speed is shown

in mm/min, if we use degrees - degree/min, if inch - inch/min. Max. speed value is very individual it

depends what motors, drives etc. were used. For the first tests, we recommend entering relatively small

value such as 2000mm/min, in case something goes wrong, we would always have enough time to press

the emergency stop E-STOP.

In the „Acceleration” area, we define the acceleration for the axis. At the beginning, we recommend to

enter something about 500mm/sec/sec. Later you can set this parameter experimentally by observing the

machine working.

Remember that after finished edition for each axis you should click on „SAVE AXIS SETTINGS”. Do the

configuration in the following order:

Open the „Motor Tuning” window

Select the axis („Axis Selection”)

Enter the parameters

”SAVE

AXIS SETTINGS”

Select the next axis

etc. Click „OK” and close the window.

„Step pulse” and „dir pulse” areas do not matter for CSMIO/IP-M. They are used to control via the LPT port

and they define the width and the STEP/DIR pulse time. The CSMIO/IP-M controller provides the signal

with the 50% duty cycle and STEP to DIR delay (10 us), which is the most optimal variant.

C S - L a b s . c . – C N C C S M I O / I P - M c o n t r o l l e r

Page 44