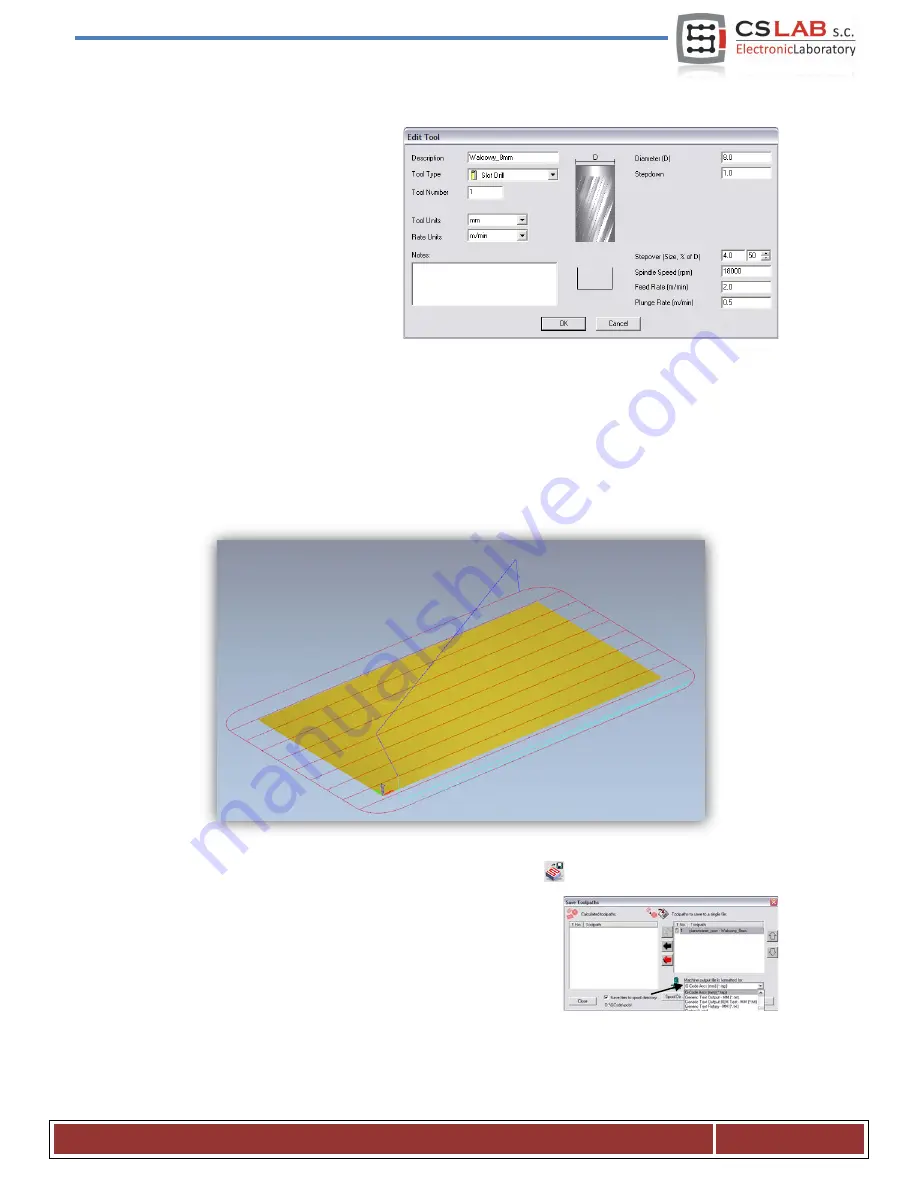

You should inform the program what kind of tool you use. Below the Tool List click the Add button. In the

tool-base window, click the Add Tool, to

add a new tool. Enter the parameters as

the picture shows. Some parameters like

description or diameter are obvious.

Step-down is a maximum depth the tool

gets. Stepover is a working density. The

bigger the density, the generally better

surface, but here it is also not worth to

overdo because you can only

unnecessarily make the treatment lasted

longer. Feed Rate is a feed on XY surface, and the Plunge Rate means speed with which the tool will get

into the material. Tool Type is a tool shape type. Here the drawing, displayed after shape type selecting, is

helpful.

In the end press „OK”, choose our tool from the list and click Select.

In the Tool List box, in the Area Clearance configuration panel there should our tool appear, now only press

Calculate: Now in the bottom of the panel, in the preview of the working area there should the calculated

tool trajectory appear. We can switch to a 3D view to look closer. It should look something like this:

Now we record the trajectory, go to the Toolpaths tab and click the

icon.

In the record window select so-called postprocessor, thus define the

output data format suitable for our control system. In the ArtCam

we recommend the „G-Code Arcs (mm) (*.tap)”. It’s basic G-Code

format suitable for Mach3 program. When you select the format

pres „Save” and save our trajectory as e.g. „planning.tap”.

C S - L a b s . c . – C N C C S M I O / I P - M c o n t r o l l e r

Page 57