Operators Manual

15

A FRESH APPROACH TO VENDING

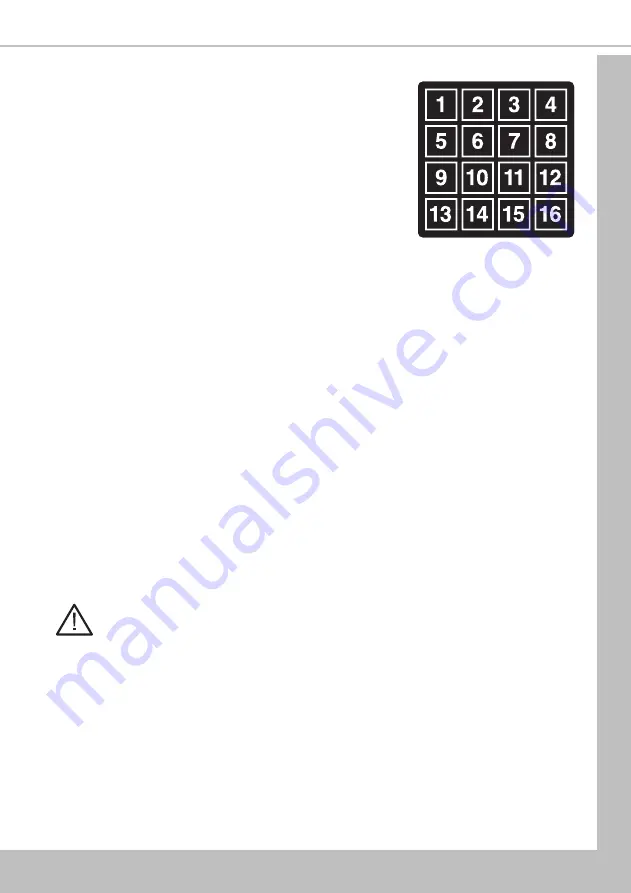

Section 5 - Service Keypad Functions

Your machine is fitted with a service keypad mounted on the rear of

the door. This keypad contains the Operators Program entry key

and also allows the operator to carry out specific functions during

routine cleaning and maintenance.

N.B. During certain operations e.g. View Counters it is necessary

for the operator to utilise the LCD mounted on the front of the door

to access data.

The service keypad allows the operator to carry out the following

functions:

5.1 Button 1 - Program Entry

This button enables the operator to access the Operators Program.

5.2 Button 2 - Brewer Open (Freshbrew Models Only)

This button operates the brewer fitted to freshbrew machines and enables the operator to replace

the filter paper used in paper type brewers or remove the brewer chambers/wipe arms assembly of

paperless brewers for cleaning purposes.

5.3 Button 3 - Rinse/Flush

1.

The flush sequence operates automatically and rinses the mixing bowls. Before the

sequence begins, the system waits until the water in the boiler is at the correct

temperature determined by the thermistor.

2.

In order to guarantee the highest standards of cleanliness, the boiler fill valve is

disabled, ensuring that the water used in the sequence is delivered at the optimum

temperature to kill any micro-organisms.

3.

Each hot water valve and the corresponding whipper is switched on in sequence for a

pre-set flush time. Once the flush cycle is complete the machine returns to standby

mode, ready to vend.

4.

To flush the machine:

a.

Open the front door of the machine.

Caution: Ensure that a suitable container is placed under the dispense position. Keep

hands away from the dispense area whilst the flushing cycle is in operation.

b.

Press and release the Flush button (3). The flush sequence begins.

c.

Empty the waste water container when complete.

5.4 Button 4 - Brewer Clean (Freshbrew Models Only)

1.

The brewer clean button enables the brewer to be cleaned independently. In order to

guarantee the highest standards of cleanliness, the boiler fill valve is disabled, ensuring

that the water used is delivered at the optimum temperature to kill any micro-

organisms.

2.

The brewer unit is filled with hot water and then operated through four complete brew

cycles.

3.

Once the cleaning cycle is complete, the boiler refills and when the water is at the

Se

ctio

n 5

- S

erv

ice

K

ey

pa

d F

un

ctio

ns