46

12

Maintenance

Validation Check

Perform the following gas and temperature checks after all cleaning, disinfecting and sterilizing or at

least every two weeks to ensure the G185 is operating correctly.

Gas Calibration

It is VERY important that the G185 is not emptied of gas during calibration. To do so will cause unstable

gas levels and gas flow, and will result in a considerable time before the gas concentration is recovered

and becomes stable again. To ensure the G185 is not emptied of gas during the gas sampling please

follow these instructions. Always use a gas analyzer recommended by CooperSurgical. The calibration

procedure described here assumes the use of the G100 Gas Analyzer (Order Code: 11103) which

recirculates gas into the gas flow during sampling.

There are two methods for collecting gas samples from the incubator:

1.

Via the Gas Sample Port on the back of the unit

2.

Via each of the chamber lids

DO NOT

collect more than 0.1l of gas from the chambers.

Always check the gas concentration in the setpoint menu during sampling. If the gas concentration

differs more than 0.1% from the setpoint, allow the G185 to stabilize to the gas concentration setpoint

before taking the next gas sample.

Please note:

If not recirculating the gas, allow the incubator to stabilize for 3 minutes after each

sample collection. Ensure the gas analyser is prepared as per its user manual.

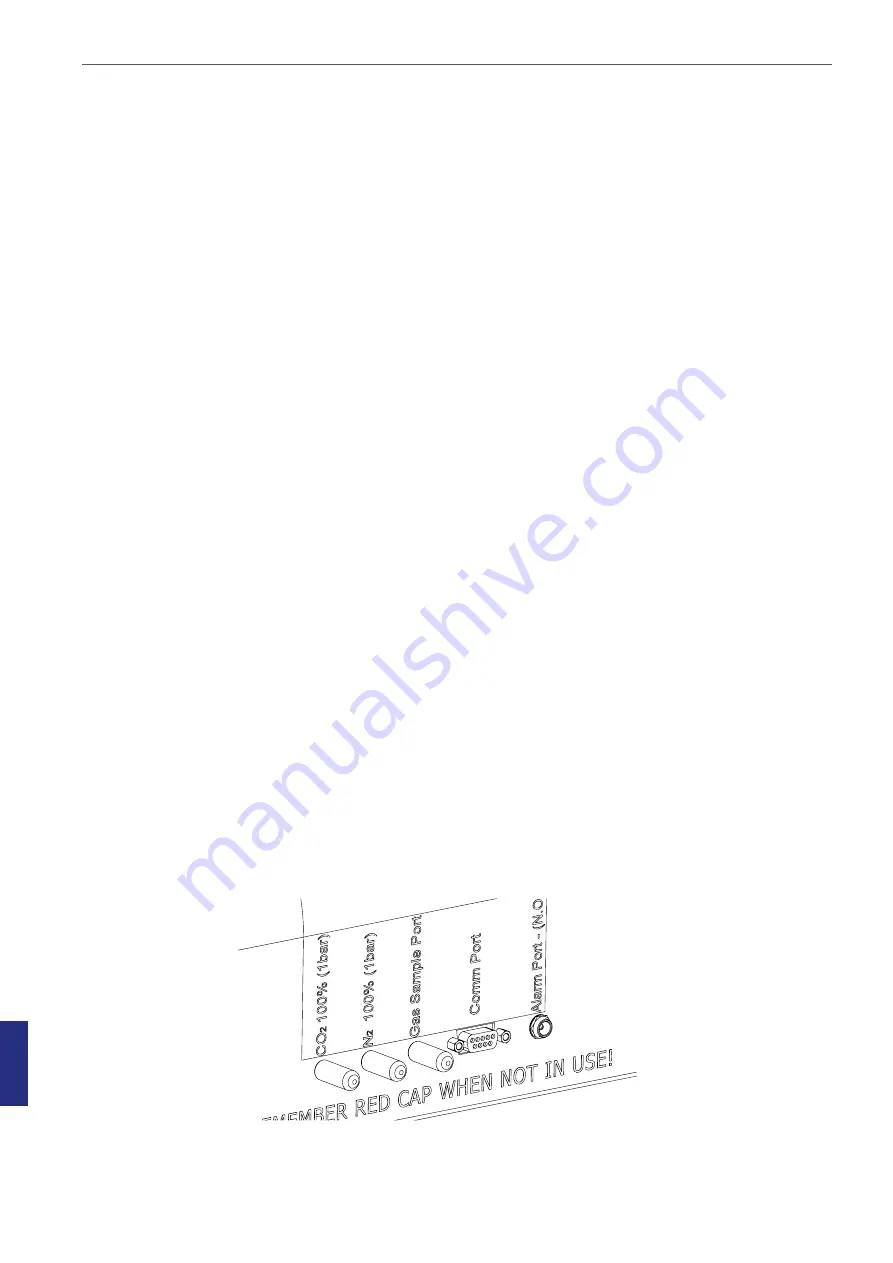

Via the Gas Sample Port

Remove the red cap from the Gas Sample Port and attach to the inlet of your gas analyzer. Make sure

•

there are no tubing leaks

•

the tubing between the sample port and gas analyzer is as short as possible, never more than

20cm

•

outside air is not drawn in

Compare the CO

2

readout with the value shown in the ‘CO2.C’ menu and adjust if necessary, see

NOTE:

Remember to put the protective red cap back on the port.

Summary of Contents for K-Systems G185 SensorTech

Page 55: ...55 11 Troubleshooting...