Page | 28

VASTRAJET

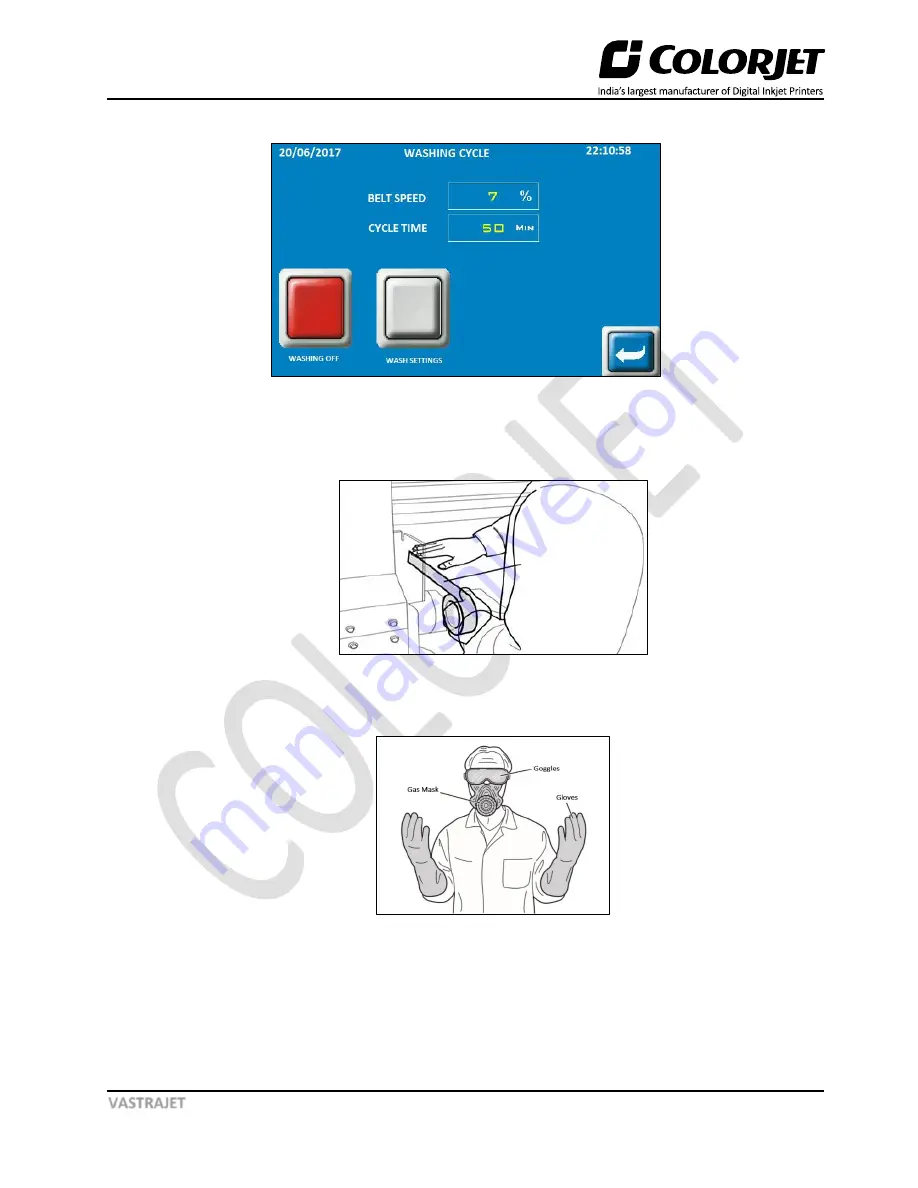

Step 3:

Run the

Wash Cycle

from HMI, simultaneously belt can be cleaned by wiping with cloth.

Fig 22: Running the Wash Cycle

Step 4:

Put masking PVC tape on both edges of the Conveyor Belt, by simultaneously moving the belt

through HMI in slow speed.

Fig 23: Using Masking Tape

Step 5:

Put on gloves, goggles, and face mask for safety

Fig 24: Using Safety Precautions

Step 6:

Keep ready the following items:-

•

Glue container(500-600ml), whichever required

•

Home cleaner liquid spray

•

Pouring container