10

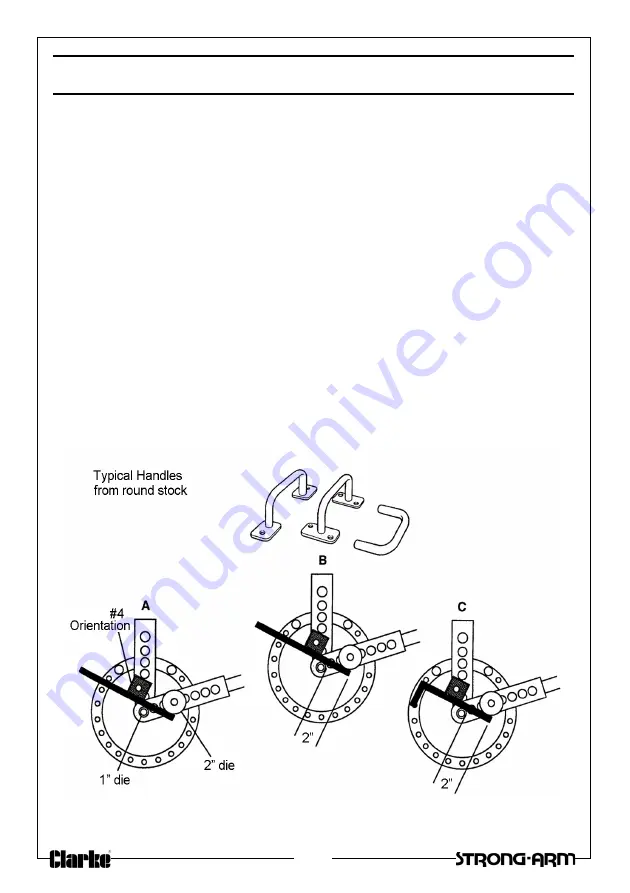

EXAMPLE: BENDING HANDLES

HANDLES FROM ROUND STOCK

To make a typical handle, using a 9in. length of 3/8in. round stock and two

pieces of flat stock:

NOTE:

To make other sizes of handles, experiment to find the

appropriate die sizes and stop block orientation.

1. With a long hinge pin, attach the handle and ring loops at their centre-pin

holes. Install a 1in. die on the centre pin. With the short hinge pin, install a 2

in. die in the handle (#2 hole).

2. With a long hinge pin, install the stop block (oriented as in A).

3. Insert the round stock into the Bender so that it extends 2” beyond the

centre-pin die (see B), and make the first bend to 90°.

4. Turn the part end-for-end, position it as in C, and make the second 90°

bend. Remove the stock from the bender.

5. Drill 5/8”holes in the flat stock & insert the handle halfway through the holes

Always drill the holes the same size as the diameter of the handle stock.

6. Weld the flat stock pieces in place from the back side. If any weld material

extends below the surface of the flat plate, grind it flush.