Installing the HD Module in the Chassis

25

3

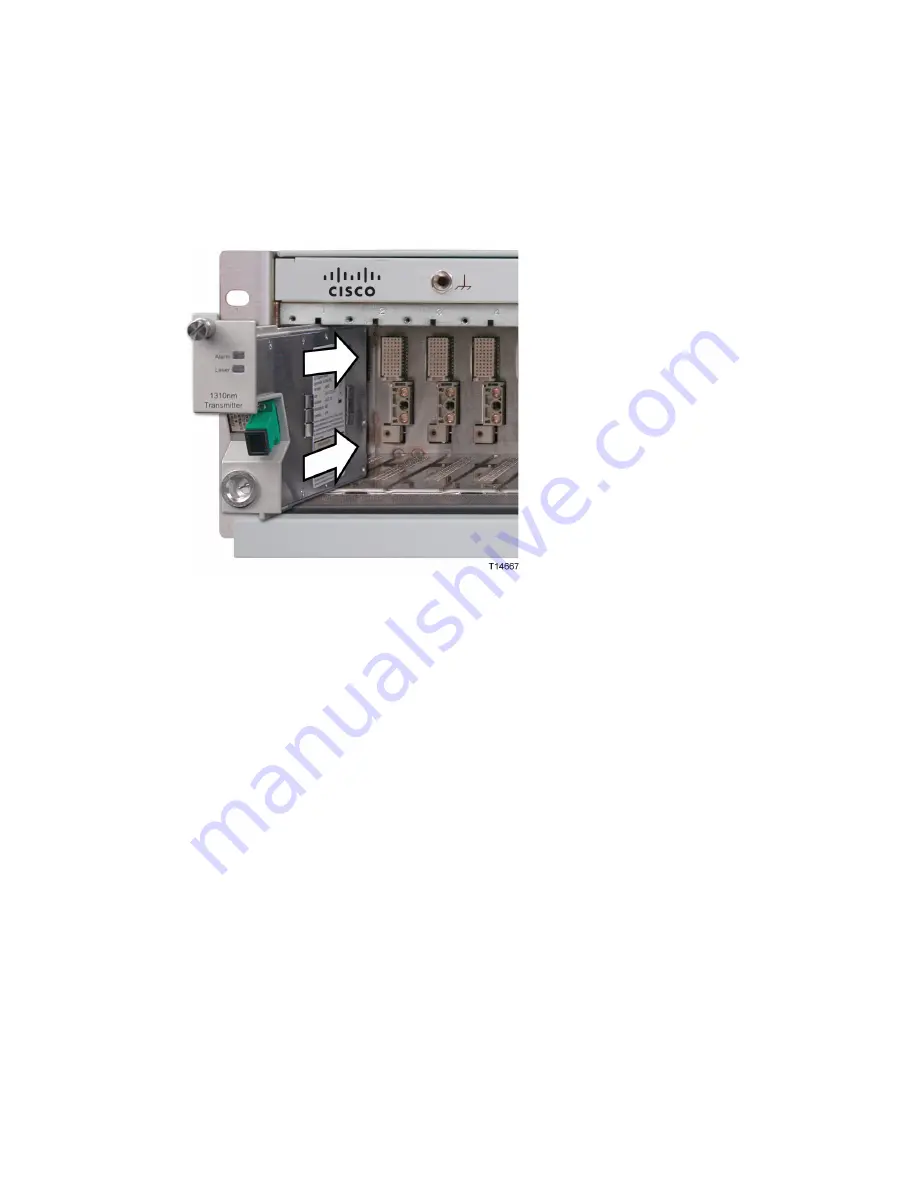

Gently slide the module into the chassis until its power and

communications connections join connectors on the midplane bus.

Do not

force the module into the chassis

. If properly aligned, it should slide in with

minimal force.

4

Tighten the screw at the top of the module to secure it in the chassis. Use a

3/8-in. flat-blade screwdriver to secure.

Do not over-tighten

.

5

Fill any unused chassis slots with module blanks to help ensure proper

cooling air flow.

Summary of Contents for Prisma II HD-LRMW

Page 2: ......

Page 20: ......

Page 29: ...Description 5 ...

Page 60: ...Chapter 2 Module Installation 36 ...

Page 64: ...Chapter 3 Operation Using the ICIM 40 ICIM2 Front Panel ICIM2 Illustration Front Panel ...

Page 86: ......

Page 95: ...Connecting Your Computer to the Chassis 71 Prisma II XD Chassis Top Right Corner Detail ...

Page 110: ......

Page 116: ......

Page 127: ......