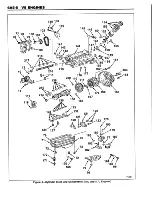

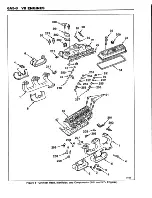

1. EXHAUST MANIFOLD

260. PUSHROD GUIDE

4. BOLT/STUD

301. STUD

6. HEAT SHIELD ASSEMBLY

302. COOLANT OUTLET

21. INTAKE MANIFOLD

303. THERMOSTAT

22. INTAKE MANIFOLD GASKET

304. GASKET

23. INTAKE MANIFOLD SEAL

309. ROCKER COVER GASKET

30. ROCKER COVER BOLT

310. OIL FILLER CAP

31. SUPPORT

311. COOLANT TEMPERATURE SENSOR

32. ROCKER ARM COVER

312. SPARK PLUG

40. ROCKER ARM BOLT

313. ENGINE LIFT BRACKET

41. ROCKER ARM BALL

314. SPRING LOCK WASHER

42. ROCKER ARM

315. BOLT

43. PUSHROD

316. STUD

44. HYDRAULIC LIFTER

317. BOLT

45. CYLINDER HEAD BOLT

318. ENGINE LIFT BRACKET

46. CYLINDER HEAD

319. STUD

47. CYLINDER HEAD GASKET

320. EGR ELECTRONIC VACUUM

251. VALVE STEM KEY

REGULATOR SOLENOID VALVE BRACKET

253. VALVE SPRING CAP

321. NUT

255. VALVE SPRING DAMPER

322. CLAMP

256. VALVE SPRING

323. HOSE

257. VALVE STEM OIL SEAL

324. CLAMP

259. INTAKE VALVE

325. NIPPLE

V1207

Figure 11— Cylinder Head, Manifolds, and Components (7.4L Engine) - Legend

DISASSEMBLY OF THE ENGINE

TOOLS AND SHOP EQUIPM ENT

A clean, well lit work area should be available. Other

necessary equipment includes: a suitable parts cleaning

tank, compressed air supply, trays to keep parts and

fasteners organized, and an adequate set of hand tools.

An approved engine repair stand will help prevent

personal injury or damage to engine components.

Special tools are illustrated throughout this section

and listed at its end. These tools (or their equivalents)

are specially designed to quickly and safely accomplish

the operations for which they are intended. The use of

these tools will also minimize possible damage to

engine components.

Some precision measuring tools are required for

in sp e ctio n of ce rta in critica l com ponents. Torque

wrenches will be necessary for correct assembly of var

ious parts.

ACCESSORY REMOVAL

This manual assumes that the engine accessories

have been removed. These accessories may include

one or more of the following:

• Power Steering Pump

• Distributor

• AIR System Pump

• Generator

• Air Conditioning Compressor

• EGR Valve and Emission Control Equipment

• Cooling Fan

It is beyond the scope of this section to detail the

many different accessory installations. Refer to the

proper Truck Service Manual for this information.

Diagrams of emission and vacuum hose routings, wir

ing harness routing, accessory drive belt layout, etc.,

should be made before removing accessories.

CLEANING

Remove the engine accessories before cleaning to

provide better access to the engine’s exterior surfaces.

After removing the TBI unit, distributor, etc., cover the

openings with tape to prevent the entry of coolant, sol

vent, and dirt.

Methods used to clean the engine will depend on

what equipment is available. Steam cleaning, pressure

washing, or solvent cleaning are some acceptable

methods. Allow the engine to dry before beginning the

work.

It is important that the engine be as clean as possible

to prevent dirt from entering critical areas during disas

sembly.

DRAINING TH E ENG INE

Remove or Disconnect

1

. Oil pan drain plug. Allow the oil pan to drain.

2. Oil filter.

3. Block drain plugs. Allow the coolant to drain.

Summary of Contents for Light Duty Truck 1994 Series

Page 1: ......

Page 11: ...VIEW A p n n n j VIEW C F7554 Figure 10 Hydra Matic 4L60 E Transmission I D Location ...

Page 24: ...NOTES ...

Page 26: ... ...

Page 69: ...NOTES ...

Page 71: ...3 2 STEERING ...

Page 73: ......

Page 84: ......

Page 102: ...40 ...

Page 130: ...NOTES ...

Page 146: ...NOTES ...

Page 162: ...NOTES ...

Page 166: ...Figure 5 Removing the Pinion Flange Figure 6 Pressing the Drive Pinion from the Cage ...

Page 178: ...Figure 3 Spreading the Differential Case Figure 4 Removing the Differential ...

Page 190: ...NOTES ...

Page 202: ...NOTES ...

Page 206: ...F5785 ...

Page 212: ...B Button Moved Out of Bearing Bore F5791 ...

Page 228: ...NOTES ...

Page 232: ......

Page 234: ......

Page 236: ...Adjuster 63 Bolt 64 Lock Figure 10 Turning the Adjuster Plug K3 Models ...

Page 237: ...Figure 13 Removing the Pinion Seal 39 Bearing Cup Figure 16 Removing the Inner Bearing Cap ...

Page 261: ...F7475 ...

Page 267: ...B Button Moved Out of Bearing Bore F5791 ...

Page 294: ...NOTES ...

Page 300: ...NOTES ...

Page 318: ...NOTES ...

Page 322: ...SR207LN2 EDS ...

Page 324: ......

Page 326: ...OVERHEAD OILING AND RETURN MAIN OIL GALLERY N30005 6A2 J EDS ...

Page 368: ...103 153 127 V1200 ...

Page 370: ......

Page 372: ......

Page 374: ...F9375 Figure 7 Engine Lubrication Diagram Engines Without Balance Shaft ...

Page 376: ...Figure 9 Engine Lubrication Diagram Engines With Balance Shaft ...

Page 399: ...V2974 ...

Page 410: ......

Page 412: ...195 196 201 174 252 163 165 164 244 3706r3924 ...

Page 452: ......

Page 454: ...163 164 V1202 ...

Page 456: ...20 21x 302 210 4 0 41 2 5 2 5 1 2 51 4 2 e3 54 3 9 252 252 S 255 255 25 6 256 209 V1196 ...

Page 458: ...100 1 8 4 185 183 177 v 75 201 3706r1204 ...

Page 460: ......

Page 510: ......

Page 512: ...V2131 ...

Page 514: ...110 106 106 103 90 93 89 88 87 86 v 7 7 7 7 j A _ 111 f t 2 a a s 53 49 L 47 46 3706r4751 ...

Page 566: ...NOTES ...

Page 574: ...NOTES ...

Page 618: ...SPECIAL TOOLS ...

Page 620: ...NOTES ...

Page 672: ......

Page 682: ......

Page 686: ......

Page 694: ...RH0213 4L60 E ...

Page 695: ...657 659 m i J 8092 H J 34196 4 3 34196 5 657 658 665 J 23907 J 7004 1 J 8092 RH0214 4L60 E ...

Page 696: ...J 8092 J 34196 4 33 31 J 8092 RH0215 4L60 E ...

Page 697: ...SPECIAL TOOLS ...

Page 698: ...SPECIAL TOOLS ...

Page 758: ...RH0194 4L80 E ...

Page 764: ......

Page 770: ...SPECIAL TOOLS ...

Page 771: ...SPECIAL TOOLS CONT ...

Page 772: ......

Page 775: ......

Page 776: ......

Page 785: ......

Page 804: ...NOTES ...

Page 806: ......

Page 808: ......

Page 822: ...3707r5079 ...

Page 840: ......

Page 848: ...NOTES ...

Page 852: ......

Page 860: ...F5435 ...

Page 866: ......

Page 878: ...F9167 ...

Page 882: ...16 FrontOutputShaft 18 DrivtQNr 19 DrivenGm t 20 DriveChain 22 FrontOutputBearing V2836 ...

Page 890: ...F9168 ...

Page 908: ......

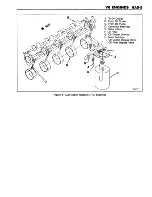

Page 919: ......