3. Crankshaft from the cylinder block with extreme

care, taking care to avoid damage to crankshaft

journals and thrust flange surfaces.

4. Upper main bearing inserts.

M AIN BEARING REMOVAL

(W ITH O U T REMOVING

CRANKSHAFT)

Important

Check the main bearing caps for location markings.

M ark the caps if necessary. The caps must be

returned to their original locations during assembly.

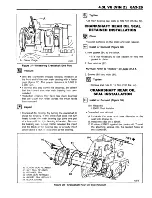

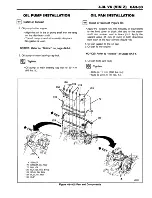

Remove or Disconnect (Figure 22)

Tool required:

J 8080 Main Bearing Remover/Installer

1. Main bearing cap bolts.

2. Main bearing caps.

3. Lower main bearing inserts from the main bearing

caps.

4. Upper main bearing inserts.

A. Insert J 8080 into the crankshaft oil hole (figure

22

).

B. Rotate the crankshaft to turn the upper main

bearing insert out of the block.

CLEANING, INSPECTION, AND REPAIR

A solvent tank large enough to hold the larger engine

parts will be needed as well as various bristle brushes

and gasket scrapers. A source of compressed air will

also be helpful in the cleaning operations.

Special tools are listed and illustrated throughout this

section with a complete listing at the end of the section.

These tools (or their equivalents) are specially designed

to quickly and safely accomplish the operations for

which they are intended. They should not be used in

operations for which they are not designed. These spe

cial tools, when they are properly used, will also mini

mize possible damage to engine components.

Some precision measuring tools are required for

inspection of certain critical components. These include

micrometers, torque wrenches, feeler gages, dial indica

tor set, etc. The inspection work, when performed with

the proper methods and tools, is most important. The

rebuilt engine cannot be expected to perform properly if

the parts are worn beyond acceptable limits are reused.

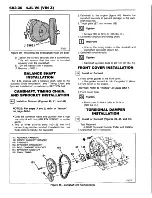

BLOCK

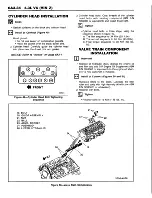

Clean (Figure 23)

1. Block with solvent.

2. All traces of old gaskets.

3. Cylinder bores.

4. Threaded holes.

5. Oil galleries and passages.

6. Scale deposits from coolant passages.

L*

Inspect

1. All expansion plugs for lack of fit or leakage.

2. Valve lifter bores for deep scratches and deposits.

3. Cracks in the block.

— Cylinder walls.

— Coolant jackets.

— Engine mount bosses.

— Main bearing webs.

4. Main bearing bores and caps.

• All main bearing bores should be rounded and

uniform in ID at all of the bearing supports.

• The area were the main bearing inserts contact

the main bearing bore should be smooth.

• If a main bearing cap is found to be damaged,

replace the cap and line-bore the block.

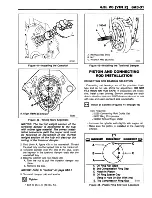

5. Cylinder head mounting surface for flatness, using

a precision straight edge and feeler gage (figure

24).

A. Set the straight edge on the sealing surface to

be inspected.

B. Take the feeler gage and at various locations,

check the gap between the straight edge and

the sealing surface.

C. If the gap is greater than 0.25 mm (0.010 inch)

at any sealing location, the block must be

replaced.

D. If the gap is less than 0.25 mm (0.010 inch) at

any sealing location and a cause for leakage is

suspected, then the minor irregularities may be

carefully machined from the block.

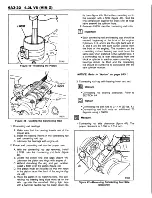

6. Oil pan, timing cover, and intake manifold mounting

surfaces for nicks. Minor irregularities may be

cleaned up with a flat file.

CYLINDER BORE

L *

Inspect

Summary of Contents for Light Duty Truck 1994 Series

Page 1: ......

Page 11: ...VIEW A p n n n j VIEW C F7554 Figure 10 Hydra Matic 4L60 E Transmission I D Location ...

Page 24: ...NOTES ...

Page 26: ... ...

Page 69: ...NOTES ...

Page 71: ...3 2 STEERING ...

Page 73: ......

Page 84: ......

Page 102: ...40 ...

Page 130: ...NOTES ...

Page 146: ...NOTES ...

Page 162: ...NOTES ...

Page 166: ...Figure 5 Removing the Pinion Flange Figure 6 Pressing the Drive Pinion from the Cage ...

Page 178: ...Figure 3 Spreading the Differential Case Figure 4 Removing the Differential ...

Page 190: ...NOTES ...

Page 202: ...NOTES ...

Page 206: ...F5785 ...

Page 212: ...B Button Moved Out of Bearing Bore F5791 ...

Page 228: ...NOTES ...

Page 232: ......

Page 234: ......

Page 236: ...Adjuster 63 Bolt 64 Lock Figure 10 Turning the Adjuster Plug K3 Models ...

Page 237: ...Figure 13 Removing the Pinion Seal 39 Bearing Cup Figure 16 Removing the Inner Bearing Cap ...

Page 261: ...F7475 ...

Page 267: ...B Button Moved Out of Bearing Bore F5791 ...

Page 294: ...NOTES ...

Page 300: ...NOTES ...

Page 318: ...NOTES ...

Page 322: ...SR207LN2 EDS ...

Page 324: ......

Page 326: ...OVERHEAD OILING AND RETURN MAIN OIL GALLERY N30005 6A2 J EDS ...

Page 368: ...103 153 127 V1200 ...

Page 370: ......

Page 372: ......

Page 374: ...F9375 Figure 7 Engine Lubrication Diagram Engines Without Balance Shaft ...

Page 376: ...Figure 9 Engine Lubrication Diagram Engines With Balance Shaft ...

Page 399: ...V2974 ...

Page 410: ......

Page 412: ...195 196 201 174 252 163 165 164 244 3706r3924 ...

Page 452: ......

Page 454: ...163 164 V1202 ...

Page 456: ...20 21x 302 210 4 0 41 2 5 2 5 1 2 51 4 2 e3 54 3 9 252 252 S 255 255 25 6 256 209 V1196 ...

Page 458: ...100 1 8 4 185 183 177 v 75 201 3706r1204 ...

Page 460: ......

Page 510: ......

Page 512: ...V2131 ...

Page 514: ...110 106 106 103 90 93 89 88 87 86 v 7 7 7 7 j A _ 111 f t 2 a a s 53 49 L 47 46 3706r4751 ...

Page 566: ...NOTES ...

Page 574: ...NOTES ...

Page 618: ...SPECIAL TOOLS ...

Page 620: ...NOTES ...

Page 672: ......

Page 682: ......

Page 686: ......

Page 694: ...RH0213 4L60 E ...

Page 695: ...657 659 m i J 8092 H J 34196 4 3 34196 5 657 658 665 J 23907 J 7004 1 J 8092 RH0214 4L60 E ...

Page 696: ...J 8092 J 34196 4 33 31 J 8092 RH0215 4L60 E ...

Page 697: ...SPECIAL TOOLS ...

Page 698: ...SPECIAL TOOLS ...

Page 758: ...RH0194 4L80 E ...

Page 764: ......

Page 770: ...SPECIAL TOOLS ...

Page 771: ...SPECIAL TOOLS CONT ...

Page 772: ......

Page 775: ......

Page 776: ......

Page 785: ......

Page 804: ...NOTES ...

Page 806: ......

Page 808: ......

Page 822: ...3707r5079 ...

Page 840: ......

Page 848: ...NOTES ...

Page 852: ......

Page 860: ...F5435 ...

Page 866: ......

Page 878: ...F9167 ...

Page 882: ...16 FrontOutputShaft 18 DrivtQNr 19 DrivenGm t 20 DriveChain 22 FrontOutputBearing V2836 ...

Page 890: ...F9168 ...

Page 908: ......

Page 919: ......