23

and clicking calibrate to verify the component is now centered;

(4)

Save:

Saves the set offsets for the PCB calibration;

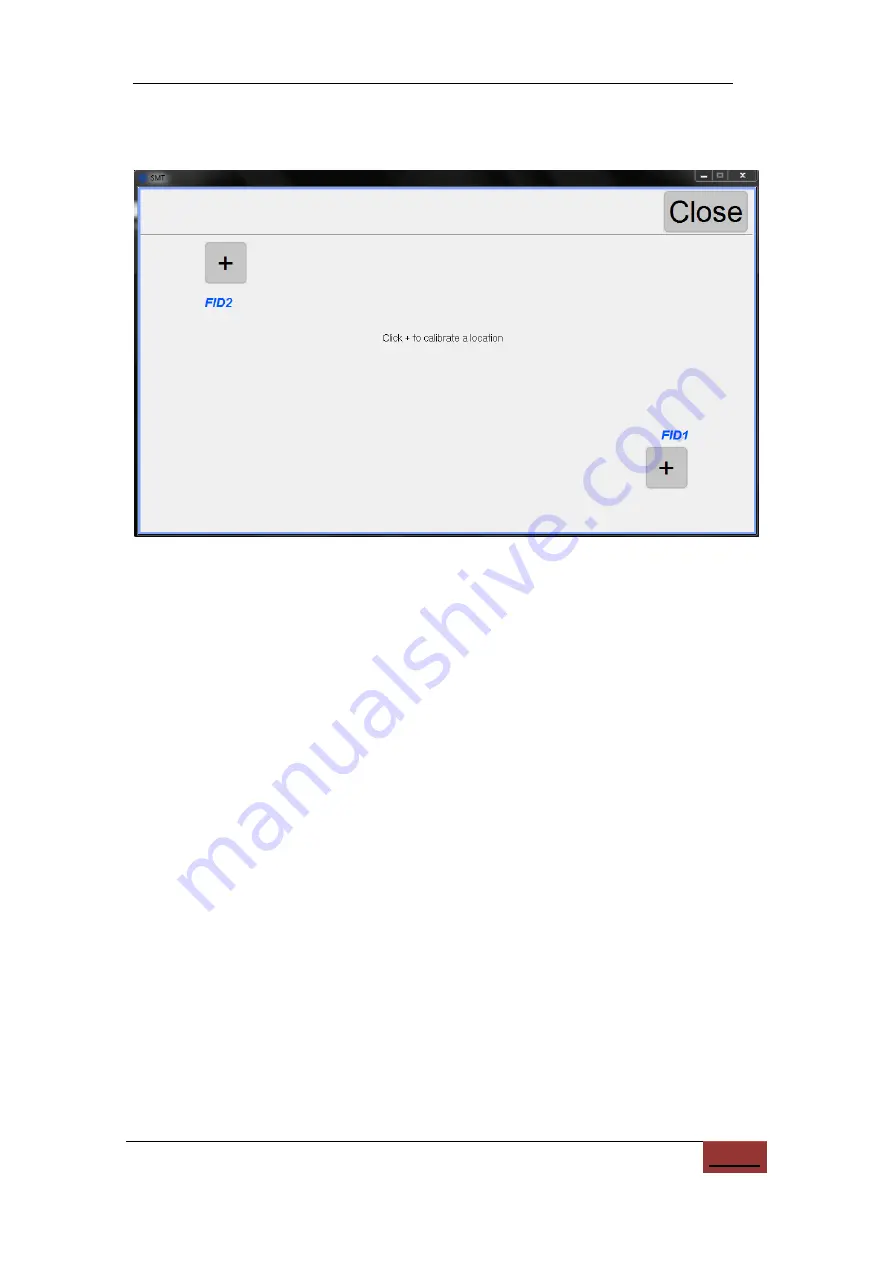

Figure

10.17.

Window for calibrating PCB points.

10.2. Load Work File

The load work window is used to run the machine and monitor its progress.

(1)

Current step:

Showing current component step and total number, click to set the

component step which will mount next;

(2)

PCB ID:

For batch mode, show current PCB ID number and total. Click to set

current PCB number, which will mount next;

(3)

Place count.:

Show total count of placed components;

(4)

PCB count:

For batch mode, show total count of PCB boards;

(5)

Average speed:

Show average mounting speed, in chips per hour;

(6)

Elapsed time.:

Run time;

(7)

Adjust Tray Start:

When feeders are defined in the IC tray, this button appears.

Click to set the start IC number;

(8)

Up camera (bottom left):

Click to watch image of up camera;

(9)

Down Light (2

nd

left):

Click to toggle light on and off;

(10)

PCB calibrate (3

rd

left):

Click to calibrate the PCB position;

(11)

Vacuum checks (4

th

left):

Click to toggle on and off the vacuum checks;

(12)

Head to Home (5

th

left):

Click to send head to home position, at back-right

;