Appendix C: Troubleshooting Errors Reported By CNC11

Symptom or Error

Limit Tripped

4. Limit tripped messages

(cont)

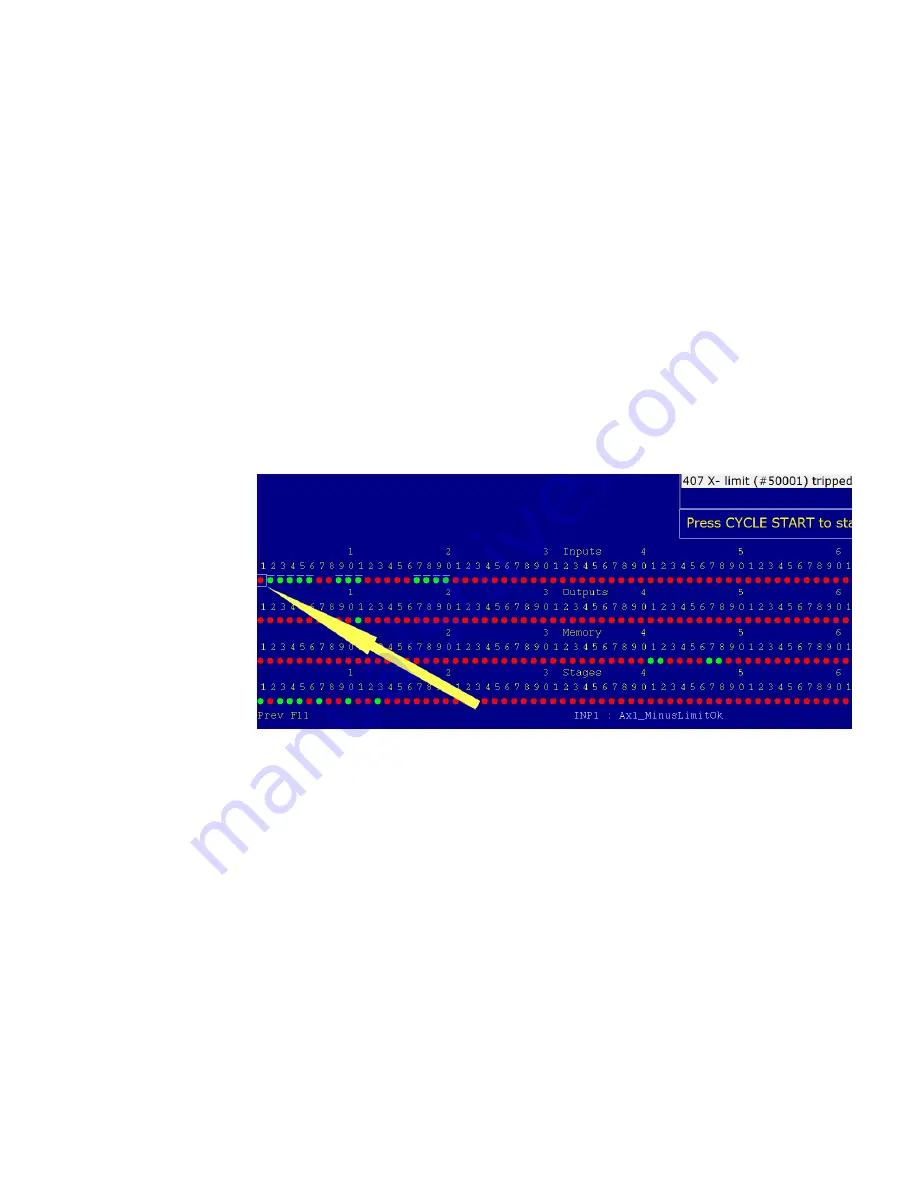

#2 Open up the real-time I/O screen by pressing alt-i while at the main

screen. Physically clear all limit switches in question by either manually

moving the axis or axes to the center of travel or removing the switch or

dog to clear it. Manually trip the limit in question and confirm that the

PLC input specified in the motor configuration toggles from green to red

when tripped. Example: In the motor configuration screenshot on the

previous page, the X- PLC input is defined as PLC input #1. In the

screenshot below it can be confirmed the X- limit is configured correctly

because, when the X- limit is tripped, PLC input #1 turns red and when

it's cleared it turns green. Check that the motor configuration for the limit

in question is correct by toggling the limit switch and confirming that the

correct PLC input toggles. If a different PLC input changes states when

the limit is tripped, enter that PLC input number in the motor

configuration page. If no PLC input changes states when the limit is

tripped, check your wiring or your switch.

Symptom or Error

Encoder quadrature or

5. Encoder quadrature or differential error

These errors are almost

differential error exclusively caused by faulty wiring or noisy encoder signals. The

best solution would be to correct the wiring being sure to always use

shielded, twisted pair cabling and/or replace the encoders. While we

don't recommend it, sometimes it is possible to simply disable these

errors in parameters 332-335 without any measurable consequence in

accuracy. To disable differential and quadrature errors on the first 8

encoder inputs, enter a value of 255 for parameters 332 to 335.

Symptom or Error

Check MPG cable

6. Check MPG cable

This message is extraneous. Ignore it.