82

13.7 Formulation Mode

This function is convenient for making many measurements of minute samples and seeking

the total mass. In this mode with any unit, when a sample is placed on the pan and [PRINT]

key is pressed, that value is output via the RS-232C cable or DATA I/O connect and automatic

taring is performed each time afterwards. This is repeated every subsequent time a new

sample is placed and [PRINT] key is pressed. Pressing the [POWER] key stops the

Formulation mode. When stopped, the measurements up to that point are summed up and

displayed. When the optional printer or computer is connected, the start up is printed out as “--

------- FORMULATION MODE ---------” and upon stop, the total is printed out as

“TOTAL=”.

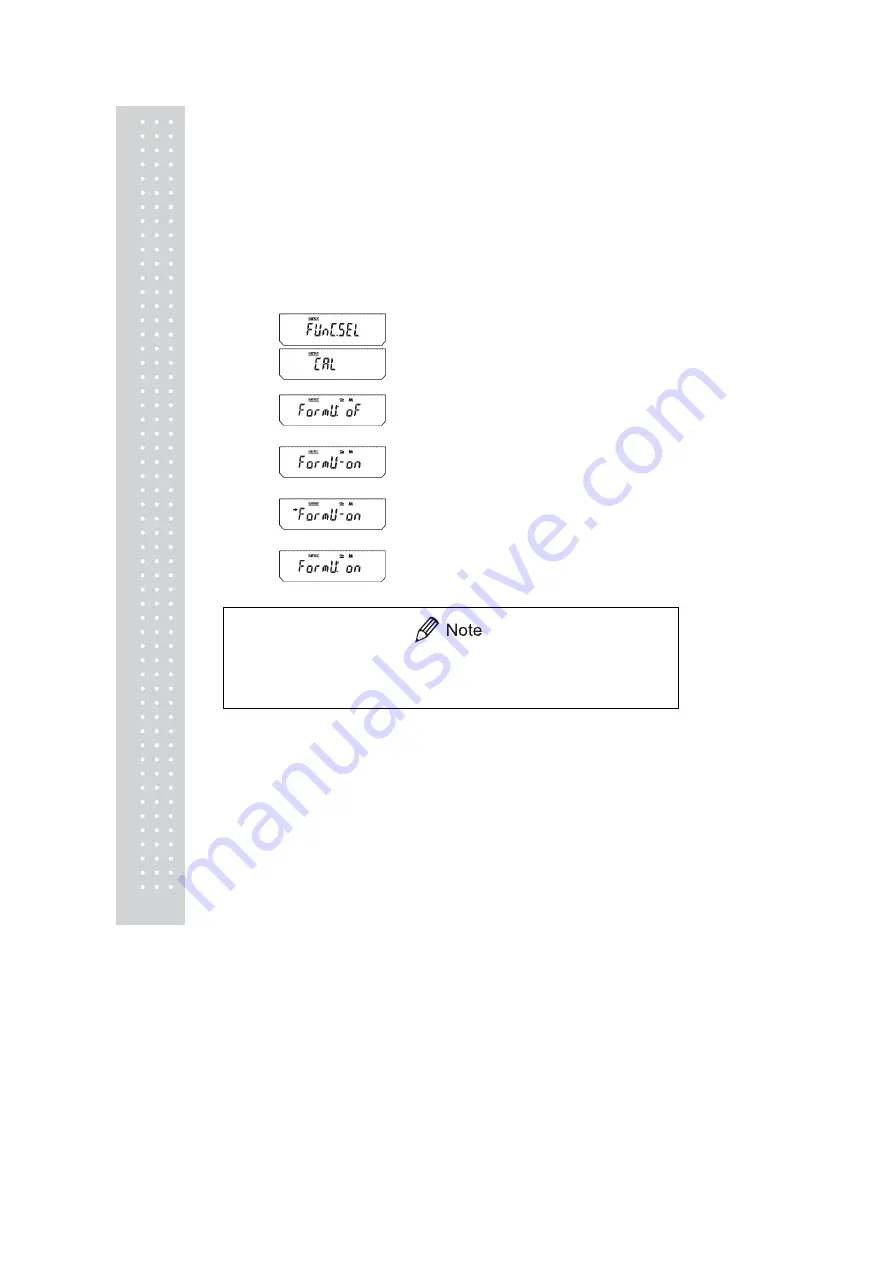

(Setting Formulation Mode)

1

Press the

[CAL]

key repeatedly from the mass

display until “FUnC.SEL” appears. Press the

[O/T]

key. The display will show “CAL”.

2

Press the

[CAL]

key repeatedly until “Formu:**”

appears. The “**” shows the current setting, “on”

for on, “oF” for off.

3

Press the

[O/T]

key. The display shows “Formu-on”

and after this, pressing the

[CAL]

key switches

the displays between “Formu-on” and “Formu-oF”.

When the current setting is displayed, the stability

mark (

¨

) appears. Press the

[O/T]

key when the

desired setting is shown, to change the setting, or

4

Press the

[POWER]

key to return to “Formu: **”.

5

Pressing the

[POWER]

key again returns to the

mass display.

No more than one of the four application modes, Auto Print (13.4), Interval

Timer (13.5), Add-on Mode (13.6), Formulation Mode (13.7) can be set ON

at the same time.

(When OFF)

(When OFF)

Setting

check

(Example)

(Example)

During

setting

(When ON)

(When ON)

During

setting

(Example)

(Example)

Setting

check

Summary of Contents for CAU Series

Page 1: ...2 ...

Page 5: ...6 ...

Page 117: ...118 MEMO ...

Page 118: ...119 ...

Page 119: ...120 ...