27

Depending on the current operating type, the active setpoint

can be selected:

• By choosing the active setpoint in the General

Parameters menu (Setpoint Select, GENUNIT).

• Via the volt-free contacts (see section 3.7.3).

• Via network commands [SP_SEL].

• Via the schedule setting (schedule 2).

The following table summarises the possible setpoint selections

based on the control type (local, remote, network) and the

following parameters:

• Heating/Cooling operating mode.

• Setpoint select.

• Setpoint selection contact status.

• Schedule 2 status for setpoint selection [SP_OCC].

Parameters status

Active

setpoint

Mode

SP_SEL

(Local/Net)

Setpoint select

(Local/Net)

Setpoint

occupancy

[SP_OCC]

Setpoint switch

(Remote)

cooling

1

sp 1

-

cooling setpoint 1

2

sp 2

-

cooling setpoint 2

3

sp 3

-

ice storage setpoint

0

auto

occupied

cooling setpoint 1

0

auto

unoccupied

cooling setpoint 2

0

auto

holiday

cooling setpoint 2

heating

1

sp 1

-

heating setpoint 1

2

sp 2

-

heating setpoint 2

3

sp 3

-

heating setpoint 3

0

auto

occupied

heating setpoint 1

0

auto

unoccupied

heating setpoint 2

0

auto

holiday

heating setpoint 3

8.5.2 - Reset

Reset.means.that.the.active.control.point.is.modified.so.that.

the machine capacity required is adjusted to be as close as

possible to the demand.

The reset source can be provided by one of the following:

• Outdoor air temperature (that gives a measure of the

load trends for the building).

• Return water temperature (heat exchanger delta T

gives an average building load).

• 4-20 mA reset signal (4-20 mA signal / external

temperature reading indicates the load trend).

The.source.of.the.reset.can.be.configured.in.the.Heat/Cool.

Config.menu.(HCCONFIG)..In.response.to.a.change.in.the.

outside temperature, delta T, or 4-20 mA reset signal reading,

the control point is reset to optimise unit performance.

To set Cooling / Heating Reset Select

1..Navigate.to.the.Configuration.menu.

2. Select

Heat/Cool Config

(HCCONFIG).

3. Set

Cooling Reset Select

[cr_sel] OR

4. Set Heating Reset Select [hr_sel].

Cooling Reset Select [cr_sel]

Heating Reset Select [hr_sel]

0 = none

1 = OAT

2 = delta T

3 = 4-20mA

The units use two control point reset types, cooling control

point reset or heating control point reset. Dry cooler condenser

option has condensing setpoint reset which can be applied if

the condensing setpoint control depends on outdoor air

temperature reading (reset source = OAT).

Cooling mode (30WG / 30WGA / 61WG)

Cooling control point reset is used to control the evaporator

water temperature reset. Heating control point reset is not

used for temperature control in the condenser water loop.

Heating reset may be used to reset the condensing setpoint

for optimised condenser operation. This is only possible on

the outside temperature. Delta T is not used.

Heating mode (30WG / 61WG)

Heating control point reset is used to control the condenser

water temperature reset.

In both cases (cooling and heating mode) the reset parameters,

i.e..slope,.reset,.and.maximum.value,.are.configurable.in.the.

Reset.Configuration.menu.(RESETCFG).

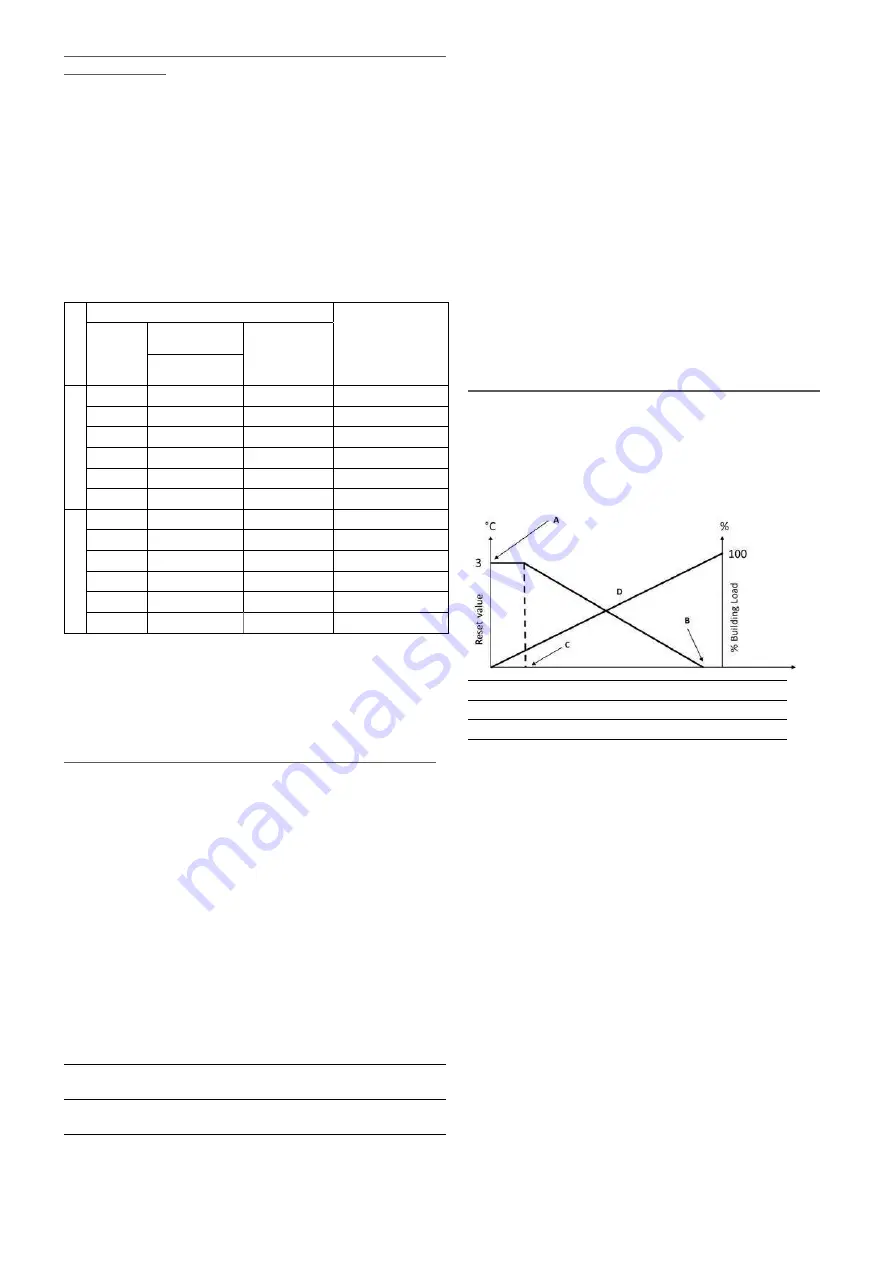

Reset is a linear function based on three parameters:

• A reference at which reset is zero (outdoor temperature

or delta T or 4-20 mA signal – no reset value).

• A reference at which reset is maximum

(OAT or delta T or 4-20 mA signal – full reset value).

• The maximum reset value.

Reset example in Cooling mode

10

Outdoor air temperature (OAT)

20

3

Heat exchanger delta T

5

4

Analogue input

20

no reset

selection

full reset

Legend:

A: Maximum reset value

B: OAT / delta T / 4-20 mA for no reset

C: OAT / delta T / 4-20 mA for full reset

D: Building load

8.6 - Capacity control

The Touch Pilot Junior control adjusts the number of active

compressors to keep the heat exchanger temperature at its

setpoint. The precision with which this is achieved depends

on.the.capacity.of.the.water.loop,.the.flow.rate,.the.load,.and.

the number of stages available on the unit.

To determine the optimum moment at which to add or

withdraw a capacity stage, the control system continuously

takes account of the temperature error with respect to the

control point, as well as the rate of change in this error and the

difference between entering and leaving water temperatures.

If the unit undergoes too many starts within an hour or the

compressor runs below one minute each time it is started, this

automatically brings about reduction of compressor starts, which

makes the controlled leaving water temperature less precise.

The high pressure, low pressure or water loop conditions can

also affect temperature control accuracy. Compressors are

started and stopped in a sequence designed to equalise the

number of start-ups (value weighted by their operating time).