DPM III xi series

Machine Overview

04.18

Operating manual

11

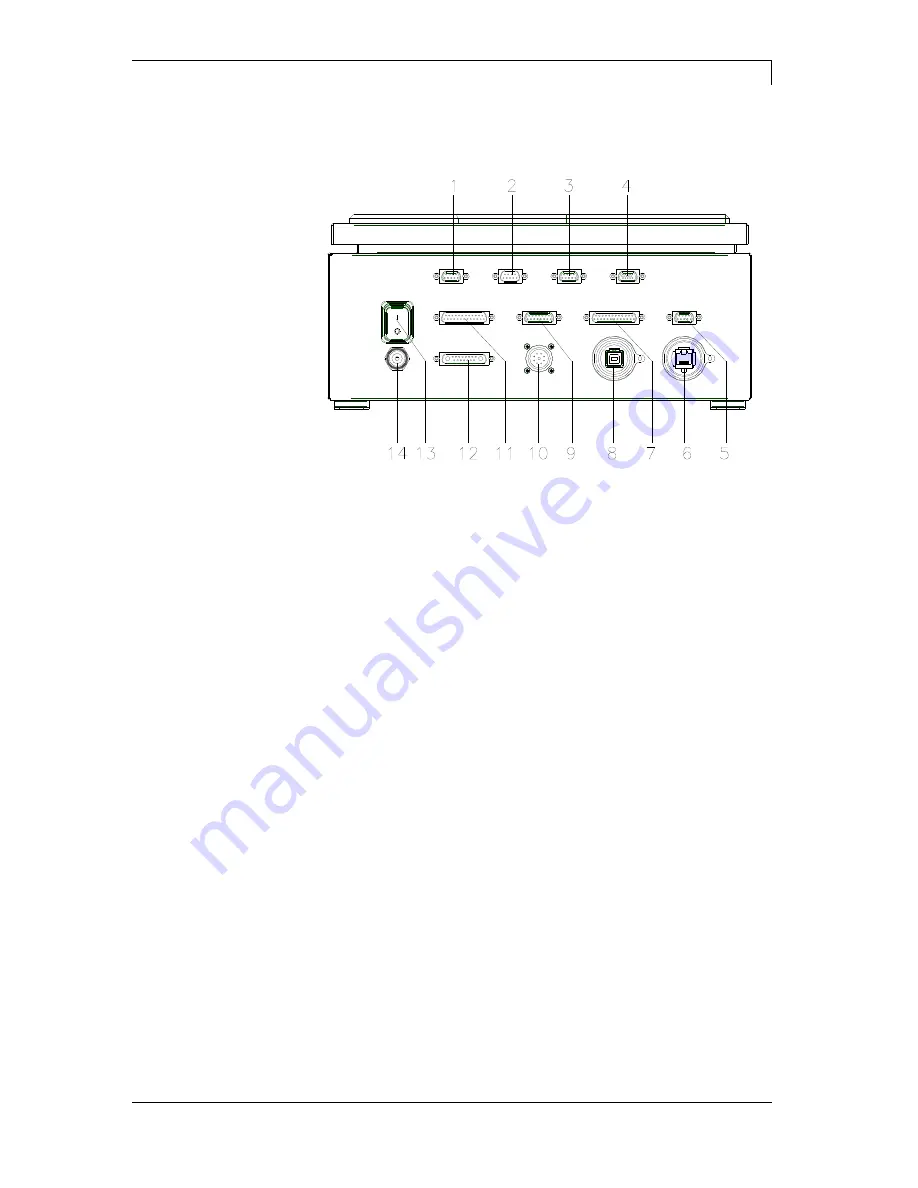

2.3 Connector Assignment of Control Unit IP Version

Figure 3

1 =

External output 1-4 (Output I)

2 =

External input 1-4 (Input I)

3 =

External output 5-8 (Output II)

4 =

External bushing I/O-24

5 =

RS-232 interface

6 =

Ethernet interface

7 =

Centronics interface

8 =

USB interface

9 =

Connecting cable sensors

10 = Connecting cable power

11 = Connecting cable signal

12 = Connecting cable motor

13 = Power switch

14 = Electric supply

Summary of Contents for DPM III XI

Page 1: ......

Page 8: ......

Page 22: ...Technical Data DPM III xi series 22 Operating manual 04 18 Example 1 Example 2 Example 3 ...

Page 34: ......

Page 38: ......

Page 62: ......

Page 72: ...Signal Diagrams DPM III xi series 72 Operating manual 04 18 10 2 Mode 2 continuous mode ...

Page 84: ......

Page 90: ......

Page 92: ......

Page 95: ......

Page 96: ......