13

ENG

Heos

+0300078EN - rel. 1.6 - 23.11.2017

2.8 Functional

diagrams

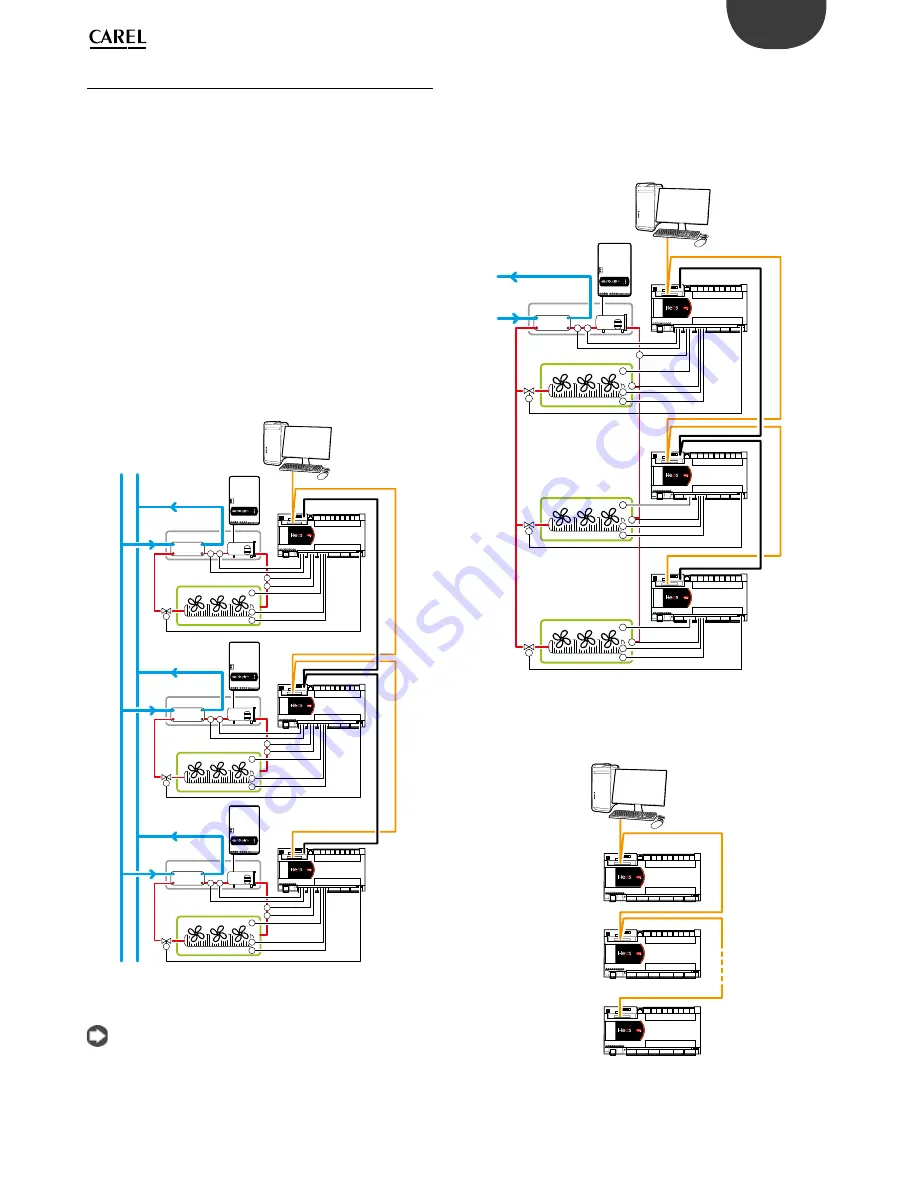

There are two possible showcase/cold/room confi gurations. The fi rst

involves the various units being fi tted individually with their own

compressor and condenser, meaning the showcase is completely

independent, and shares the cooling water loop with the rest of the

system. In the second case, the condenser is shared and consequently the

Slave showcases are only fi tted with the evaporator and corresponding

electronic expansion valve, while the compressor is controlled by the

Master board.

The system confi gurations can be set from a terminal (pGDe) as illustrated

in the chapter on Commissioning; while on the showcase itself a PLD is

normally used to display the temperature and any alarm signals.

Defrosts can be coordinated via the pLAN that controls a maximum of 6

units, or alternatively by the supervisor

1.

Stand-alone confi guration

In this case, each showcase/cold room has its own compressor, controlled

by the corresponding board, which manages all system devices

(expansion valve, showcase temperature control, alarms….).

The Master/Slave network is used for to coordinate defrosts, lights and

curtain switch; otherwise these functions must be managed by the

supervisor.

P

T

P

T

T

Waterloop

Conden. Unit

BMS

Cabinet

Master

Slave1

pLAN Net

w

o

rk

RS485 Super

visor

y S

yst

ems

Slave2

Cabinet

T

T

T

T

T

P

T

P

T

Conden. Unit

Cabinet

T

T

T

P

T

P

T

Conden. Unit

Fig. 2.n

Note:

For the electrical connections, see the general connection

diagram in par. 2.9. If a master/slave network or multi-evaporator pLAN is

confi gured, the controller addresses should be set following the

procedure shown in chapter 9.1 or using the Wizard (chap. 5

“Commissioning”)

2.

Multi-evaporator Master/ Slave network

The Master controller manages the compressor and coordinates the

functions of the 5 Slave controllers connected via the pLAN. Each Slave

controller manages the individual showcase and has a PLD user terminal

for temperature monitoring. Each controller, both Master and Slave,

is connected to the supervisor network. The Master only shares the

evaporation pressure, and not the corresponding temperature.

P

T

P

T

T

T

T

Waterloop

Conden. Unit

BMS

Cabinet

Master

Slave1

pLAN Net

w

o

rk

RS485 Super

visor

y S

yst

ems

Slave2

Cabinet

Cabinet

T

T

T

T

T

T

T

T

T

Fig. 2.o

3.

RS485 supervisor network

A maximum of 199 number Heos controllers (Master or Slave) can be

connected to the supervisor network (via CAREL or Modbus® protocol).

RS485 Super

visor

y S

yst

ems

1

2...

...199

BMS

Fig. 2.p

Supervisor network layout with various Heos controllers connected,

1-199

Summary of Contents for Heos

Page 2: ......

Page 4: ...4 ENG Heos 0300078EN rel 1 6 23 11 2017 ...

Page 6: ......

Page 57: ...57 ENG Heos 0300078EN rel 1 6 23 11 2017 Notes ...

Page 58: ...58 ENG Heos 0300078EN rel 1 6 23 11 2017 Notes ...

Page 59: ......